TEST 3: Manually Inducing A Lean Air/Fuel Mixture

In this test, we're going to force a lean condition to see if the rear oxygen sensor responds to it. We'll create this condition by carefully introducing a small vacuum leak at the brake booster hose.

This will allow unmetered air to enter the intake manifold, making the air/fuel mixture leaner —and if the rear oxygen sensor is working properly, it should react to the change.

It doesn't necessarily have to be the brake booster hose —any vacuum hose connected to the intake manifold will work, as long as it's about the same diameter and easy to access. Just use whatever's most convenient on your setup.

IMPORTANT: Before starting the engine, loosen the vacuum hose at the brake booster so it's easy to wiggle open during the test. These hoses can be tight, and you don't want to be fighting with it while the engine is running.

Here's how to perform the vacuum leak test step by step:

- 1

Locate the vacuum hose connected to the brake booster.

- 2

With the engine OFF, gently break the seal by loosening the hose at the booster port.

The goal here is to make sure the hose can be easily cracked open while the engine is running. Once loosened, reseat the hose snugly onto the booster. - 3

Plug in your scan tool and access the "live data" section.

- 4

Start the engine and let it warm up completely.

You want the PCM to enter closed loop mode —check your scan tool to confirm that it has. - 5

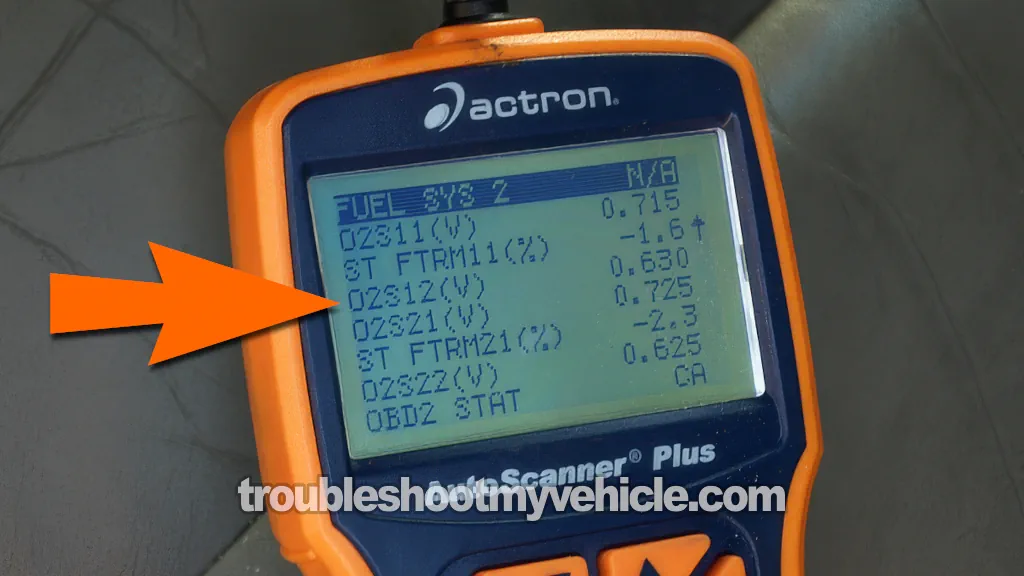

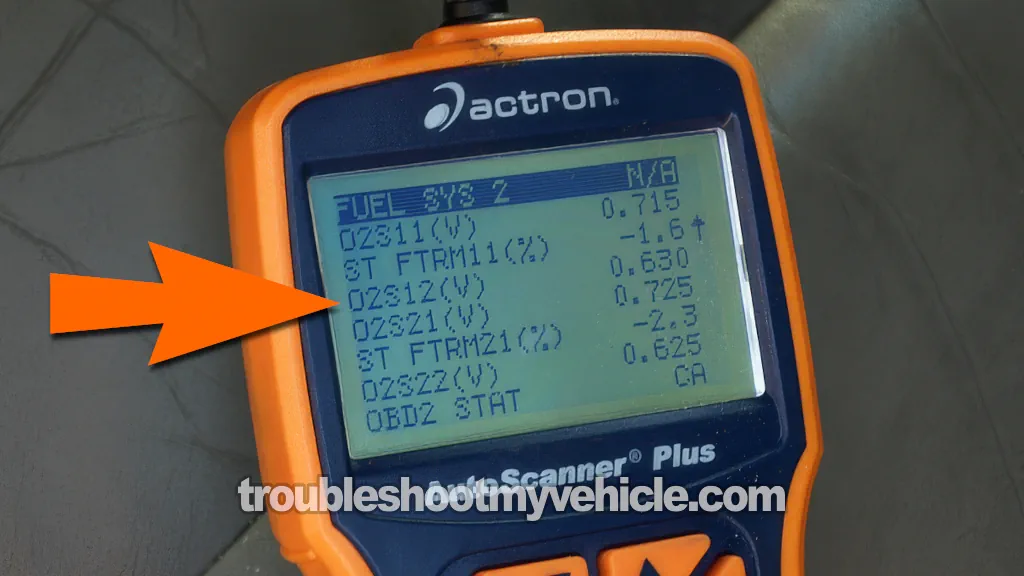

Look for the Parameter ID (PID) labeled O2S12.

This is the rear (downstream) oxygen sensor —the one located after the catalytic converter. - 6

Carefully crack open the hose just enough to let a small amount of unmetered air in.

NOTE: Don't pull the hose off completely —this can stall the engine. You want a small, controlled leak.

If the engine stalls, reseat the hose, restart the engine, and try again with a smaller opening. - 7

Watch the rear O2 sensor voltage (usually labeled O2S12) on your scan tool.

If the sensor is functioning properly, the voltage should drop below 0.5 Volts in response to the lean condition. - 8

When finished, reseat the vacuum hose firmly and shut off the engine.

Let's see what your test means:

CASE 1: The rear O2 sensor voltage drops immediately below 0.5 Volts. This confirms the sensor is capable of detecting lean conditions, so far so good.

Our next step is to induce a "rich" condition and see if the rear O2 sensor reacts to it. Go to: TEST 4: Manually Inducing A Rich Air/Fuel Mixture.

CASE 2: The rear O2 sensor voltage does not respond (stays above 0.5 Volts). This indicates the sensor is not picking up the lean condition.

Either the sensor is faulty or the catalytic converter is so compromised that it's masking the lean mixture. In this case, I recommend replacing the O2 sensor and repeating the test before condemning the converter.

TEST 4: Manually Inducing A Rich Air/Fuel Mixture

Forcing a rich air/fuel condition will be our final oxygen sensor performance test. We'll do this by carefully spraying a small amount of carburetor cleaner into the engine's intake.

If you don't have carb cleaner, starting fluid or even brake cleaner spray will work —they all serve the same purpose of temporarily enriching the air/fuel mixture.

If the rear O2 sensor is functioning properly, it should immediately respond with a high-voltage signal (around 0.9 to 1 Volt), confirming it can detect a rich exhaust condition.

As before, we'll use the scan tool in live data mode to monitor the rear oxygen sensor's voltage in real time and see how it reacts.

IMPORTANT: Make sure you're working in a well-ventilated area. The engine must be fully warmed up and idling in closed loop mode. Keep a fire extinguisher within reach, and never spray near hot components or electrical connections.

All right, here's how to run the test:

- 1

Take off the air intake duct from the throttle body.

- 2

Start the engine and let it reach full operating temperature.

Make sure the PCM has entered closed loop mode, and that your scan tool is displaying live data from the rear oxygen sensor. - 3

Spray a quick, controlled burst of carburetor cleaner into the throttle body.

NOTE: A short spray —about half a second to one second— is enough. Don't overdo it. You just want to enrich the mixture briefly, not flood the engine.

If the engine stalls, you've sprayed too much cleaner. Restart the engine, let it stabilize, and repeat the test with a shorter burst. - 4

Watch the rear O2 sensor voltage on the scan tool.

If the sensor is functioning properly, the voltage should immediately jump above 0.5 Volts in response to the temporary rich condition. - 5

Let the engine settle back to normal idle before trying another spray.

Wait a few seconds so the exhaust mixture can stabilize and confirm that the sensor reacts the same way again. - 6

Once done, let the engine idle for another minute or two, then shut it off.

Here's what your test result means:

CASE 1: The rear O2 sensor voltage jumps above 0.5 Volts. That's a good sign —the sensor is alive and reacting properly to the rich condition.

If you also saw the voltage drop in TEST 3 (the lean test), then your rear O2 sensor is working as it should.

At this point (having confirmed the rear O2 sensor is good), the P0420 code is telling you that the catalytic converter is no longer doing its job and should be replaced.

CASE 2: The rear O2 sensor voltage doesn't move. That tells you the rear oxygen sensor is bad and needs to be replaced.

In this situation, it's a good idea to replace the rear O2 sensor and rerun the test before deciding to replace the catalytic converter.

What "Rich" And "Lean" Mean On An Oxygen Sensor

By now, you've probably noticed that when troubleshooting issues related to oxygen sensors or the catalytic converter, the terms "rich" and "lean" come up a lot.

They're used to describe the air/fuel mixture —and more specifically (in the case of this tutorial), how much oxygen remains in the exhaust after combustion.

Here's a detailed breakdown of each:

- Rich condition: This means the engine is getting more fuel than needed and less oxygen. In this case, the O2 sensor will show a high voltage signal —generally in the range of 0.8 to 0.9 Volts.

- Lean condition: This indicates the engine is running with more oxygen than fuel. The sensor voltage will drop low —typically around 0.1 to 0.2 Volts.

The front O2 sensor —located before the catalytic converter— should constantly switch between rich and lean. This back-and-forth signal helps the PCM make rapid fuel adjustments and maintain optimal engine performance.

On the other hand, the rear O2 sensor —positioned after the catalytic converter— behaves differently. If the converter is working, it reduces unburned fuel in the exhaust, which results in a more stable voltage from the downstream sensor. Instead of rapid switching, you'll see a slower, smoother signal.

Now, if that rear sensor is consistently reading above 0.5 Volts and not moving much, it usually means the converter isn't doing its job anymore —and the P0420 code is likely being set because of it.

There's no single magic number to look for, but the pattern matters. A rear O2 sensor that flatlines high while the front one keeps switching normally is a strong clue that the catalytic converter is no longer effective.

What "Closed Loop" Means —And Why It Matters

When you first start your engine —regardless of the outside temp— the computer (PCM) operates in what's called open loop mode.

In open loop, the PCM isn't relying on input from sensors like the oxygen sensors. Instead, it uses preset values to control fuel delivery. Basically, it's flying blind until the engine warms up.

After the engine reaches normal operating temperature, the PCM switches to closed loop mode. That's when things get interesting.

In closed loop, the PCM actively monitors the O2 sensors and other data to fine-tune the air/fuel ratio on the fly. This feedback loop helps maximize performance, reduce emissions, and ensure fuel efficiency.

If you're testing your catalytic converter or downstream O2 sensor, it's critical that the engine is in closed loop —otherwise, the sensor readings won't reflect real-world conditions.

Your scan tool can tell you when the switch happens. Look for something in the live data like "Fuel System Status: Closed Loop". That's your green light to start any diagnostic testing involving O2 sensors or cat efficiency.

Trying to check sensor data while the PCM is still in open loop will give you unreliable results —so always let the engine warm up fully before testing.

More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials

I've written several more tutorials for the V6 Chrysler, Dodge, and Plymouth minivans that you might find helpful. You can browse them all in this index:

If this info saved the day, buy me a beer!