TEST 2: Making Sure The CKP Sensor Is Getting 8 Volts

If your CKP sensor didn't produce an ON/OFF voltage signal in the last test, your next move is to check whether the PCM is sending it the required 8-volt power supply.

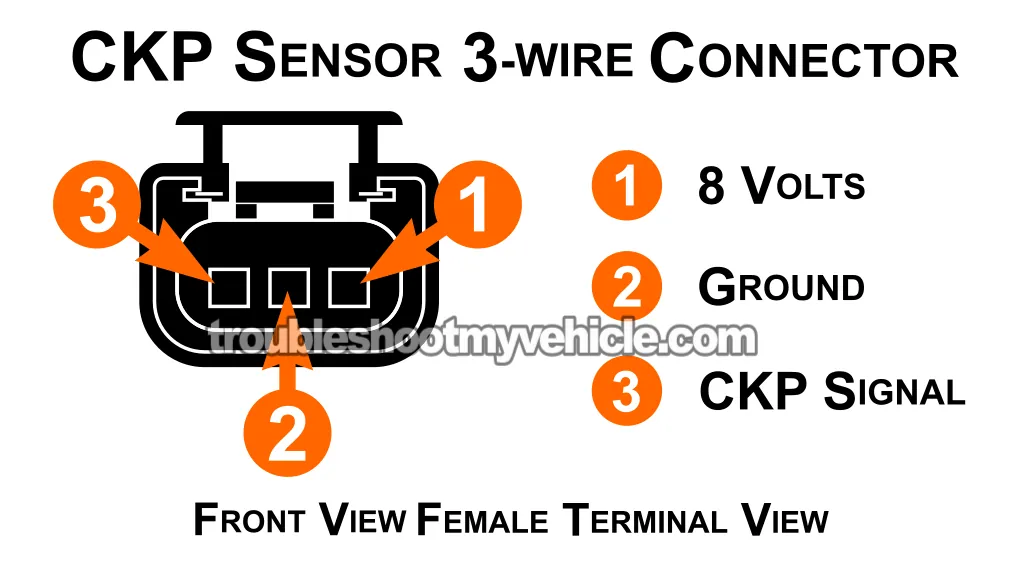

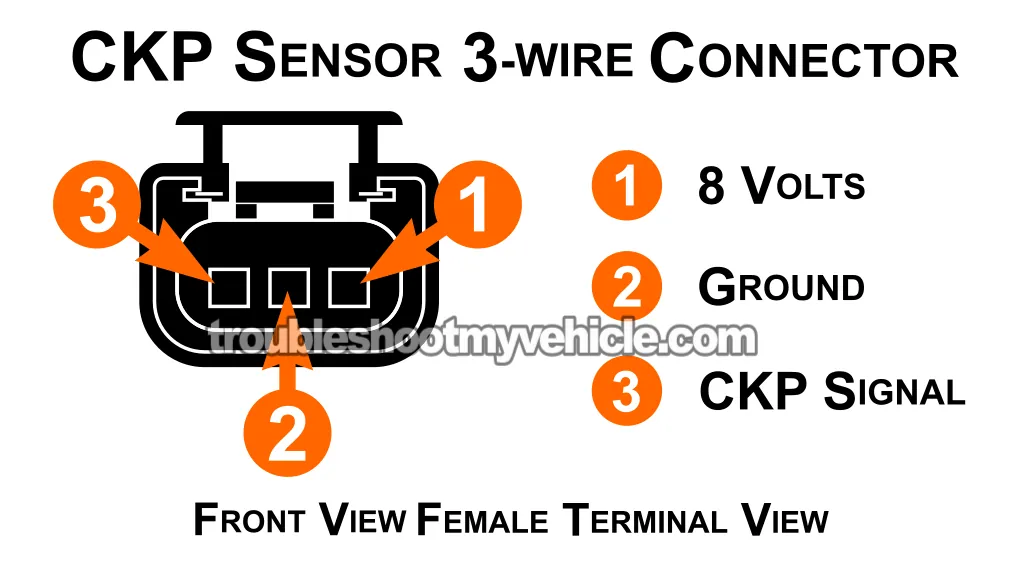

The wire that delivers this voltage to the CKP sensor is the orange (ORG) wire on the sensor's 3-wire connector.

In the connector pinout illustration above, I've labeled the terminal that connects to the ORG wire as number 1.

Here's how to check for these 8 Volts:

- 1

Unplug the crank sensor's connector.

- 2

Connect the black multimeter lead to the battery's negative (-) terminal.

- 3

Turn the ignition switch to ON (but don't crank the engine).

- 4

Set your multimeter to Volts DC mode.

- 5

Probe terminal 1 with the red multimeter test lead.

NOTE: Double-check that the terminal actually connects to the ORG wire. - 6

You should see between 7.5 and 8 Volts on your multimeter.

Alright, let's find out what it all means:

CASE 1: 7.5 to 8 Volts are present. That confirms the PCM is supplying power correctly to the CKP sensor.

Your next step is to check that it's getting Ground from the PCM. Go to: TEST 3: Making Sure The CKP Sensor Is Getting Ground.

CASE 2: You get 0 Volts. Recheck your test setup and confirm you're testing the correct terminal/wire.

If there's still no voltage, the issue likely lies with an open-circuit problem in the ORG wire, between the CKP sensor connector and the PCM connector.

Your next step is troubleshoot this missing voltage problem and repair it to restore power to the CKP sensor.

TEST 3: Making Sure The CKP Sensor Is Getting Ground

Here's what you've already confirmed up to this point:

- TEST 1: The CKP sensor isn't producing an ON/OFF signal.

- TEST 2: It's receiving its 8 Volts from the PCM.

Now it's time to check the Ground circuit —specifically the DK BLU/DK GRN wire, which runs to terminal 2 of the sensor's connector.

IMPORTANT: This Ground comes straight from inside the PCM. Never connect battery voltage to it —you'll fry the computer instantly. Instead, we'll do a voltage drop test using your multimeter.

Here's how to safely test the presence of Ground:

- 1

Unplug the CKP sensor from its connector.

- 2

Connect your red multimeter test lead to the battery's positive (+) post.

- 3

Set the ignition to ON (engine OFF).

- 4

Switch your multimeter to DC Volts mode.

- 5

Touch the black multimeter lead to terminal 2.

NOTE: Verify that the DK BLU/DK GRN wire actually connects to terminal 2. - 6

You should see a voltage reading between 10 and 12 Volts.

OK, let's interpreting your test result:

CASE 1: The multimeter registered 10–12 Volts. Nice! This means the sensor has a solid Ground path.

If you've already confirmed the sensor has power (TEST 2) and it's not generating a signal (TEST 1), it's defective and should be replaced.

Before installing the new sensor, see: Installing The CKP Sensor: Air Gap Clearance.

CASE 2: No voltage. Double-check your test connections and test again.

If there's still no 10 to 12 Volts reading, the BLK/LT BLU wire probably has an open-circuit problem between the sensor and the PCM.

You'll need to locate and fix the break in the BLK/LT BLU wire to restore the CKP sensor back to life.

Installing The CKP Sensor: Setting The Correct Air Gap

To function properly and avoid getting destroyed by the flywheel, the CKP sensor needs a precise gap between its tip and the flywheel —approximately 0.020 inches (0.5 mm).

This distance is maintained using a paper spacer that usually comes attached to the tip of a new sensor.

That spacer isn't just packaging —it's essential. Leave it in place when installing the sensor. It ensures the sensor won't sit too close and risk contact with the spinning flywheel.

If the sensor is installed without this spacer, the flywheel will slam into it during startup and wreck the sensor immediately.

If you're reinstalling the same sensor you removed, more than likely the spacer is missing (it gets scraped off by the flywheel).

In those cases, I've made a replacement using index cards —cut, stacked, and glued until it hits the 0.020-inch thickness mark. It's a solid fix when you're in a hurry and one you can also do yourself.

If you don't want to make one, you can grab a ready-made spacer online here:

- Walker Products 235-1378 CKP Sensor Spacer (at: amazon.com).

More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials

You can find a complete list of 3.3L V6 Chrysler, Dodge, and Plymouth minivan tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- P0171 Diagnostics (1996-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- P0420 Diagnostics -Catalytic Converter Tests (1996-2010 3.3L V6 Chrysler, Dodge And Plymouth Minivan).

- How To Check For Vacuum Leaks: Carb Cleaner Spray (1991-2010 3.9L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test For A Blown Head Gasket (1991-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

If this info saved the day, buy me a beer!