TEST 2: Making Sure The CKP Sensor Is Getting 8 Volts

If you didn't see an ON/OFF signal from the CKP sensor in the last test (TEST 1), there's a good chance the sensor isn't getting power.

So in this section, our next step is to check whether the PCM is supplying the 8 Volts the sensor needs to function.

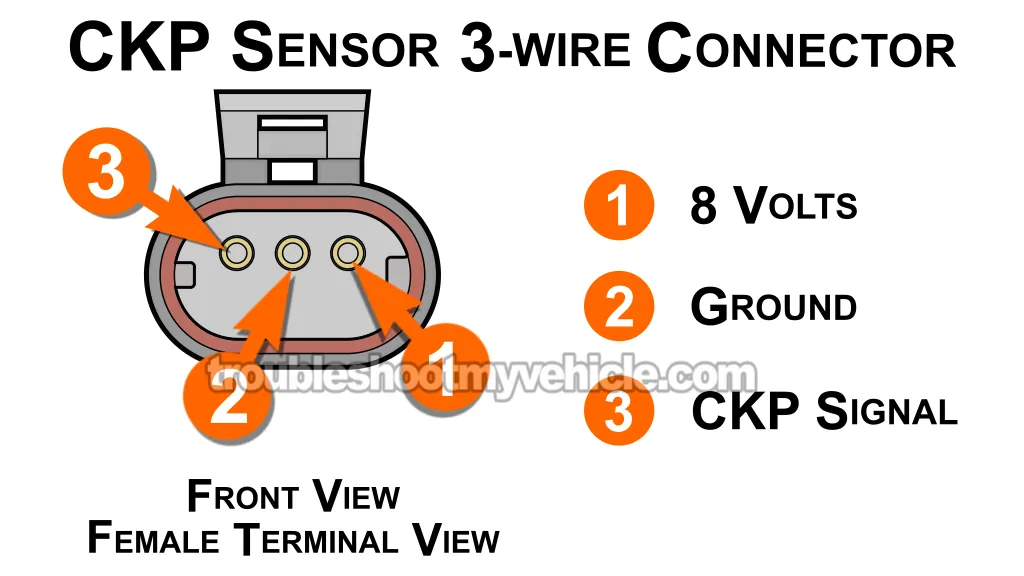

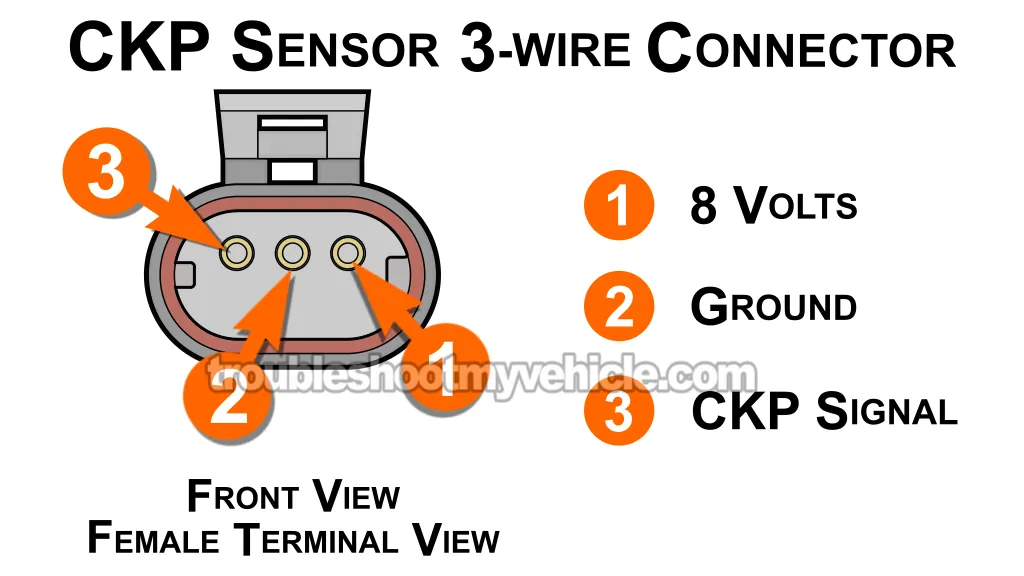

This voltage should be present at pin #1 —which connects to the orange (ORG) wire —of the sensor's engine wiring harness connector.

To verify the presence of these 8 Volts on the ORG wire, we'll do a quick multimeter voltage check with the ignition key in the RUN position (engine OFF).

Here's how to check for these 8 Volts:

- 1

Unplug the sensor connector.

- 2

Ground your black multimeter test lead at the battery's negative (-) terminal.

- 3

Set the ignition to ON (engine off).

- 4

Put your multimeter on DC voltage mode.

- 5

Touch the red multimeter test lead to terminal #1

NOTE: Verify that terminal #1 connects to the ORG wire. - 6

You should read between 7.5 and 8 Volts on your multimeter.

Results breakdown:

CASE 1: You measure 7.5 to 8 Volts. That's what you want —it confirms the PCM is powering the sensor.

Next, let's confirm the sensor has a solid Ground: TEST 3: Making Sure The CKP Sensor Is Getting Ground.

CASE 2: You measure 0 Volts. First, double-check that your multimeter leads are connected properly, then repeat the test.

If you're still seeing no voltage, it likely means the ORG wire has an open-circuit somewhere between the 3-wire sensor connector and the PCM connector.

Since the CKP sensor itself depends on that 8-volt supply to generate a signal, your next step is to track down and repair the break in the circuit to get the CKP sensor back to work.

TEST 3: Making Sure The CKP Sensor Is Getting Ground

Alright, here's what your previous two tests have ruled out:

- TEST 1: The crank sensor didn't produce its ON/OFF signal.

- TEST 2: You confirmed it's getting its 8 Volt power supply.

Now we need to test if the sensor has a proper Ground connection through the black with light blue stripe (BLK/LT BLU) wire, which connects to terminal 2.

IMPORTANT: This Ground is internally supplied by the PCM. Never apply power (12 Volts from the battery) to this wire or you'll fry the PCM. We'll do a safe and simple multimeter voltage check to confirm Ground in this circuit.

OK, this is what we need to do:

- 1

Disconnect the crankshaft position sensor.

- 2

Clip the red multimeter lead to the battery's positive (+) terminal.

- 3

Switch the key to ON, engine OFF.

- 4

Put your multimeter in DC Volts mode.

- 5

Probe pin #2 with the black multimeter test lead.

NOTE: Make sure that the BLK/LT BLU wire connects to pin #2. - 6

Your multimeter should report between 10 and 12 Volts if Ground is present in the BLK/LT BLU wire.

Let's interpret your test result:

CASE 1: You see 10–12 Volts. That confirms the sensor has a proper Ground path.

If you've confirmed it's getting power (TEST 2) and it's not generating an ON/OFF signal (TEST 1), it's time to replace the CKP sensor.

Be sure to check: Installing The CKP Sensor: Air Gap Clearance.

CASE 2: No reading. Double-check your connections and repeat the test.

If the reading still stays at zero, the Ground wire is likely open between the sensor's 3-wire connector and the PCM connector.

Without Ground, the CKP sensor can't function. Your next step is to troubleshoot and repair the issue causing the missing Ground in the BLK/LT BLU wire.

Installing The CKP Sensor: Setting The Correct Air Gap

The CKP sensor has a small air gap —or clearance— of about 0.020 inches (0.5 mm) between it and the flywheel.

This gap prevents the sensor from being damaged by contact with the flywheel and ensures it can properly detect the flywheel slots to generate its ON/OFF signal.

The gap is maintained by a thin paper spacer, usually stuck to the tip of the sensor when it's new.

This paper spacer may not look like much, but it's critical. It's glued to the sensor tip —the part that faces the flywheel— and should not be removed. It ensures the sensor sits at the correct distance once installed.

If you install the sensor without the spacer, or if it's missing, the sensor will contact the flywheel —and when you crank the engine, the flywheel will strike and destroy it.

If you're reusing the same CKP sensor (you've just removed) and the spacer's gone (the flywheel often wears it off), you can make one using something like an index card. I've personally used this method when I couldn't wait for a new spacer to arrive.

Cut small circles, stack and glue them together until you reach the needed 0.020-inch thickness. Once you've got the spacer at the correct thickness, glue it to the tip of the CKP sensor.

You can buy a replacement spacer online here:

- Walker Products 235-1378 CKP Sensor Spacer (at: amazon.com).

More 3.3L V6 Chrysler, Dodge, And Plymouth Minivan Tutorials

You can find a complete list of 3.3L V6 Chrysler, Dodge, and Plymouth minivan tutorials in this index:

Here's a small sample of the tutorials you'll find in the index:

- P0171 Diagnostics (1996-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

- P0420 Diagnostics -Catalytic Converter Tests (1996-2010 3.3L V6 Chrysler, Dodge And Plymouth Minivan).

- How To Check For Vacuum Leaks: Carb Cleaner Spray (1991-2010 3.9L V6 Chrysler, Dodge, And Plymouth Minivan).

- How To Test For A Blown Head Gasket (1991-2010 3.3L V6 Chrysler, Dodge, And Plymouth Minivan).

If this info saved the day, buy me a beer!