TEST 2: Making Sure The MAP Sensor Is Getting Power

So far, you have confirmed that the MAP sensor is not producing a decreasing/increasing MAP signal as you apply/release vacuum to it.

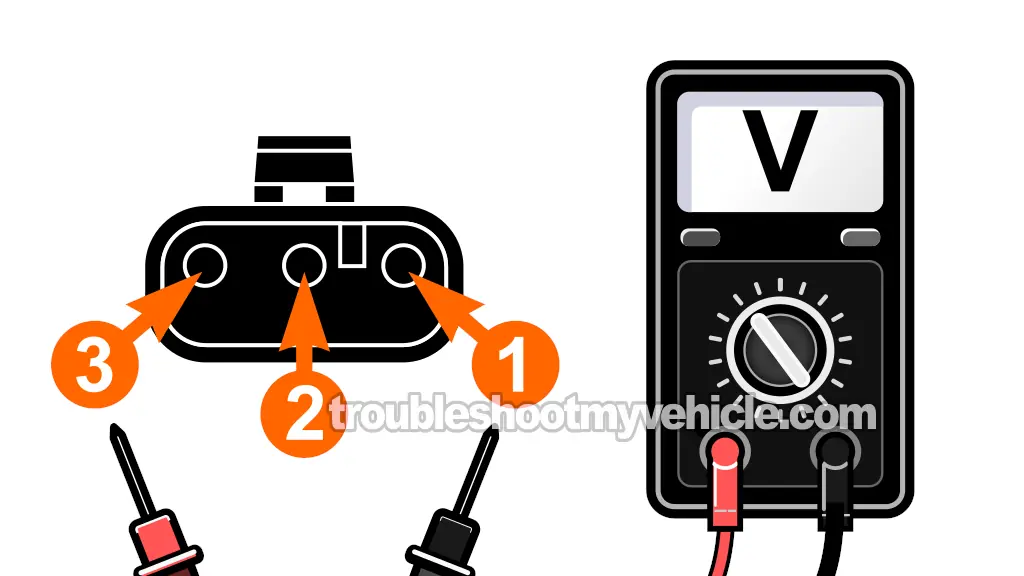

To make sure that the MAP sensor is bad, we now need to make sure it's getting power on the violet with white stripe (VIO/WHT) wire of the MAP sensor 3-wire connector.

The VIO/WHT wire is the one that connects to the terminal labeled with the number 1 in the illustration above.

This is what you'll need to do:

- 1

Place your multimeter in Volts DC mode.

- 2

Disconnect the MAP sensor from its electrical connector.

- 3

Connect the black multimeter test lead directly on the battery negative (-) terminal.

- 4

Have a helper turn the key to the RUN position, but don't crank or start the engine.

- 5

Gently probe the terminal labeled with the number 1 with the red multimeter test lead.

The female terminal labeled with the number 1 connects to to the VIO/WHT wire of the MAP sensor connector.

NOTE: Be careful not to damage the female terminal with the multimeter test lead, or you'll need to replace the connector. - 6

Your multimeter should register 4.5 to 5 Volts DC if the VIO/WHT wire is feeding the manifold absolute pressure (MAP) sensor with power.

Let's take a look at your test results:

CASE 1: 4.5 to 5 Volts are present. So far so good, since this means that the PCM is supplying power to the manifold absolute pressure (MAP) sensor.

The next step is to make sure that the PCM is feeding your 3.0L Chrysler's MAP sensor with Ground. For this test, go to: TEST 3: Making Sure The MAP Sensor Is Getting Ground.

CASE 2: 4.5 to 5 Volts ARE NOT present. Recheck your multimeter connections and retest.

If the multimeter still does not register 4.5 to 5 Volts DC, then you've found the reason for the MAP sensor code/failure.

Without 5 Volts, the MAP sensor will not function. Although testing this missing voltage is beyond the scope of this tutorial, your next step is to resolve these missing 5 Volts.

The most likely cause of these missing 5 Volts is an open-circuit problem or a short-circuit issue between the fuel injection computer's connector and the MAP sensor connector.

TEST 3: Making Sure The MAP Sensor Is Getting Ground

So far, your MAP sensor diagnostic tests have confirmed that:

- The MAP sensor is NOT producing a decreasing/increasing voltage signal when you applied/released vacuum (TEST 1).

- The DK GRN/RED wire of the MAP sensor's connector is supplying power (TEST 2).

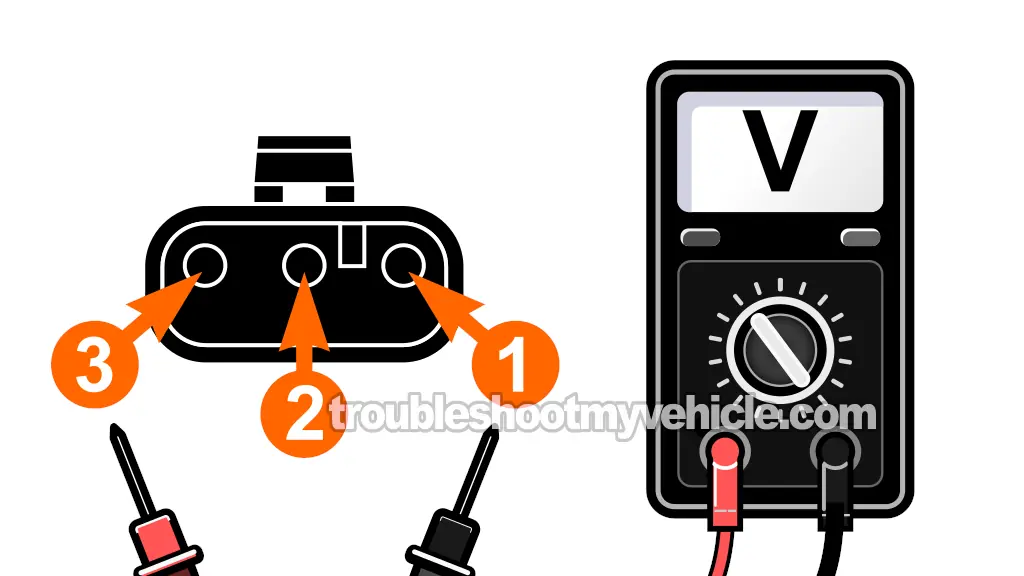

The next step and the last one is to make sure that the MAP sensor is being fed Ground by the black with light blue stripe (BLK/LT BLU) wire of its harness connector.

IMPORTANT: The PCM is the one that provides this Ground internally, so be careful and don't intentionally or accidentally connect this wire to battery voltage or you'll fry the PCM. The multimeter voltage test I'm suggesting in the test instructions is a safe way to test for the presence of Ground in the wire.

This is what you'll need to do:

- 1

Place your multimeter in Volts DC mode.

- 2

Disconnect the MAP sensor from its electrical connector.

- 3

Connect the red multimeter test lead directly on the battery's positive (+) terminal.

- 4

Have a helper turn the key to the RUN position, but don't crank or start the engine.

- 5

Gently probe the terminal labeled with the number 3 with the black multimeter test lead.

The female terminal labeled with the number 3 connects to to the BLK/LT BLU wire of the MAP sensor connector.

NOTE: Be careful not to damage the female terminal with the multimeter test lead, or you'll need to replace the connector. - 6

Your multimeter should register 10 to 12 Volts DC if the BLK/LT BLU wire is feeding the MAP sensor with Ground.

Let's take a look at your test results:

CASE 1: Your multimeter showed 10 to 12 Volts. This is the correct test result and it means that the PCM is supplying Ground to the manifold absolute pressure (MAP) sensor.

This confirms that the manifold absolute pressure (MAP) sensor is bad and needs to be replaced. Why? Well, because so far you have confirmed that:

- The MAP sensor is not producing a signal when vacuum is applied to it (TEST 2).

- The MAP sensor is getting its 5 Volts (TEST 2).

- In this test step, you've confirmed that the MAP sensor is getting Ground.

Taking all of these 3 test results, you can conclude with confidence that you need to replace the MAP sensor with a new one.

CASE 2: Your multimeter did NOT show 10 to 12 Volts. Recheck your multimeter connections and retest.

If the multimeter still does not register 10 to 12 Volts DC, then you've found the reason for the MAP sensor code/failure.

Without Ground, the MAP sensor will not function. Although troubleshooting why this Ground is missing is beyond the scope of this tutorial, your next step is to restore this Ground to the sensor.

The most likely cause of this missing Ground is an open-circuit problem or a short-circuit issue between the fuel injection computer's connector and the MAP sensor connector.

More 3.0L Chrysler Tutorials

You can find a complete list of tutorials in this index: Chrysler 3.0L Index Of Articles.

- How To Replace The Distributor (1988-2000 3.0L Chrysler).

- How To Test Engine Compression (1987-2000 3.0L Chrysler).

- How To Test The Throttle Position Sensor (1991, 1992, 1993, 1994, 1995 3.0L V6 LeBaron, Daytona, Dynasty, Monaco, Shadow, Spirit, Acclaim, Sundance).

- How To Test For A Broken Timing Belt (1998-2000 3.0L SOHC Chrysler).

- Ignition Distributor System Tests 3.0L Chrysler, Dodge, Plymouth (at: easyautodiagnostics.com).

If this info saved the day, buy me a beer!