Testing the actual fuel injector spray on a 1992–2000 3.0L V6 Dodge or Plymouth minivan is one of the best ways to track down a cylinder misfire or rough idle problem.

Just because an injector passes a resistance test doesn't mean it's delivering the right spray —clogged or restricted injectors are a common cause of performance issues on these engines.

In this step-by-step guide, I'll show you how to test the spray pattern using a simple injector cleaning tool.

Whether you're chasing a misfire, rough idle, or lean condition, this test can help you quickly find out if an injector is at fault —and avoid wasting money on unnecessary parts.

Contents of this tutorial:

- Why Testing Injector Spray Matters.

- Checking If The Fuel Injector Sprays Fuel.

- TECH TIP 1: Important Precautions When Removing The Upper Intake Manifold Plenum.

- TECH TIP 2: Always Replace Injector O-Rings.

- TECH TIP 3: Install The Intake Manifold Plenum Gasket Dry.

- More 3.0L V6 Dodge And Plymouth Minivan Tutorials.

APPLIES TO: This tutorial applies to the following vehicles:

- 3.0L V6 Dodge Caravan: 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000.

- 3.0L V6 Dodge Grand Caravan: 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000.

- 3.0L V6 Plymouth Voyager: 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000.

- 3.0L V6 Plymouth Grand Voyager: 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000.

FUEL INJECTOR RESISTANCE TESTS:

CYLINDER MISFIRE DIAGNOSTICS:

Why Testing Injector Spray Matters

It's easy to assume that if a fuel injector passes a resistance test, it must be fine. But that's not always true. I've seen plenty of injectors that measured good on a multimeter —yet were barely spraying, or worse, completely clogged.

The only way to know for sure is to check the spray pattern. On these engines, it's a little more involved —you'll need to pull the upper intake plenum to access the injectors. No way around it. (It's not bad once you know what to expect— and I'll cover that below.)

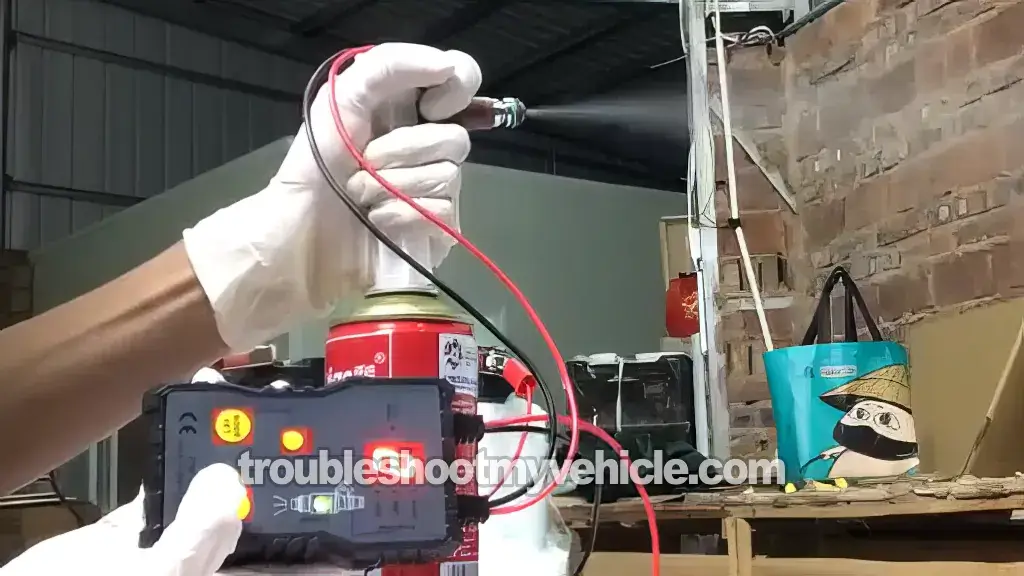

For this test, you'll use a fuel injector cleaning and spray tester tool. It's a simple setup that lets you pulse the injector outside the engine while pushing cleaner through it —so you can watch what kind of spray it produces.

The tool typically comes with two key parts:

- Pulse module: Connects to your battery and pulses the injector like the PCM does when the engine is running.

- Adapter fitting: Lets you attach the injector to a can of brake cleaner (safe for this test) so you can see what's coming out of the nozzle.

Once connected, you hit the pulse button while feeding cleaner through the injector. If the spray is a nice, fine cone-shaped mist —the injector is working like it should. But if you see a weak stream, uneven spray, or nothing at all— that injector is restricted and needs cleaning or replacement.

I use this tool all the time —and honestly, it's one of the most useful things you can have for diagnosing misfires on these 3.0L V6 engines. I only wish tools like this had been around when I first started turning wrenches decades ago!

Where to buy it:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Checking If The Fuel Injector Sprays Fuel

Safety first: You'll be working with brake cleaner (which is flammable), so it's important to take a few precautions:

- Read the tool's instructions carefully so you know exactly how it works.

- Work in a well-ventilated space —far away from sparks, open flames, or heat sources.

- Wear eye protection (safety glasses are a must).

- Wear gloves —brake cleaner isn't great for your skin.

NOTE: To safely remove a fuel injector on these 3.0L V6 minivans (1992–2000), you'll need to remove the upper intake plenum first. For more on this step, be sure to read: TECH TIP 1: Important Precautions When Removing The Upper Intake Plenum.

Here's how to perform the spray test:

- 1

Remove the upper intake plenum so you can safely access and remove the fuel injector you want to test.

- 2

Remove the injector from the engine.

- 3

Take the spray nozzle off your brake cleaner can —you won't need it for this test.

- 4

Connect the injector to the test tool's plastic adapter.

This is the adapter that connects the injector to the spray can of brake cleaner. - 5

Attach the adapter to a can of brake cleaner.

- 6

Pulse the injector using the power module.

This mimics normal injector operation —forcing brake cleaner through the injector so you can watch the spray.

Now, here's how to read your results:

CASE 1: The injector produces a fine, even spray mist. Perfect. The injector is working properly and atomizing fuel like it should.

If that cylinder is still misfiring, the problem is elsewhere —likely ignition, compression, or wiring. You can follow this guide for more help:

CASE 2: The injector doesn't spray at all. It's completely clogged. Replacement is your best bet here —a fully blocked injector usually won't respond to cleaning.

CASE 3: The injector shoots a solid stream (like a squirt gun), not a mist —It's partially clogged. You can try pulsing more cleaner through it to clear it up.

If the pattern improves into a mist —great. If not, you've got to replace it.

TECH TIP 1: Important Precautions When Removing The Upper Intake Manifold Plenum

Removing the upper plenum on these 3.0L V6 minivans isn't hard —but if you've never done it before, there are a few things you really want to be aware of first.

If you're an experienced tech, you've probably pulled a dozen of these. But for DIYers working in the garage or driveway —this job takes a little extra care to avoid turning a simple injector test into a bigger repair.

First tip: if this is your first time pulling an intake plenum, take a few minutes to read up. Whether it's a repair manual (Chilton, Haynes), or a solid YouTube walkthrough —it pays to know what's involved before you start taking parts off.

Once you're ready to begin:

- Keep small parts organized and well clear of the engine bay. Bolts, nuts, and brackets should never be left sitting on the plenum, cowl, or valve covers. All it takes is one dropped bolt to land inside an open port.

- Immediately cover all six intake runners with clean rags or shop towels once the plenum is off. Do this before doing anything else. A tiny screw or washer falling into an intake port can ruin your day —or your engine.

- Do not use RTV or sealant on the intake manifold gaskets when reinstalling the plenum. These gaskets are designed to be installed dry. Adding sealant can lead to vacuum leaks or sealing problems —and you'll end up pulling it back apart (see: TECH TIP 3: Install The Intake Plenum Gasket Dry).

IMPORTANT: If anything drops into an intake port, you'll be pulling the cylinder head to retrieve it. And if you miss it and run the engine? That stray bolt or washer can destroy valves, gouge cylinder walls, or even break pistons in seconds.

This is a very doable job —just take your time, stay organized, and cover those intake ports the second the plenum comes off. Do that, and you'll save yourself from headaches (and major engine damage).

TECH TIP 2: Always Replace Injector O-Rings

Reusing old fuel injector O-rings is a shortcut you never want to take. I've seen it lead to leaks —and even engine fires. Whenever you reinstall an injector, always use brand-new O-rings. No exceptions.

The O-rings are what seal the injector to the fuel rail and keep fuel from leaking under pressure. But once an injector has been pulled, those O-rings can easily get stretched, nicked, or develop tiny imperfections —even if they "look fine".

If an O-ring fails to seal, you could end up with fuel spraying into the engine bay —and that's a major safety hazard, especially near hot surfaces.

Here's how to do it right:

- Use O-rings that are an exact fit for your engine —don't guess.

- Before installing, lightly coat each new O-ring with clean engine oil. This helps them seat smoothly without twisting or tearing.

- Press the injector in gently and double-check that each O-ring is sitting squarely in place.

O-rings are inexpensive —but ignoring them could cost you an engine… or a lot worse. It's one of those simple steps that makes all the difference.

TECH TIP 3: Install The Intake Manifold Plenum Gasket Dry

Here's something I see a lot —RTV or gasket sealer applied to the upper intake plenum gasket when it's time to put it all back together.

But don't do it. The plenum gasket is designed to seal dry —no RTV, no gasket maker, not even a "light coat".

This goes for both the rubber style and the paper style gaskets used on these 3.0L V6 engines. Adding sealant may sound like extra insurance, but it could actually cause a problem down the road.

What problems? Vacuum leaks, poor idle, or even performance issues that will send you right back under the hood pulling the plenum off again.

To do it right: clean both mating surfaces thoroughly, install the gasket dry, torque everything to spec —and you're done.

More 3.0L V6 Dodge And Plymouth Minivan Tutorials

You can find a complete list of diagnostic tutorials in this index:

Here's a sample of the tutorials you'll find in the index:

- How To Replace The Distributor (1988-2000 3.0L V6 Chrysler, Dodge, Plymouth).

- How To Test For A Broken Timing Belt (1988-2000 3.0L SOHC Chrysler).

- How To Test The Cam Sensor (1996-2000 3.0L Caravan, Grand Caravan, Voyager, Grand Voyager).

- How To Test An Engine No-Start (1990-2000 3.0L V6 Chrysler, Dodge, And Plymouth Minivan).

If this info saved the day, buy me a beer!