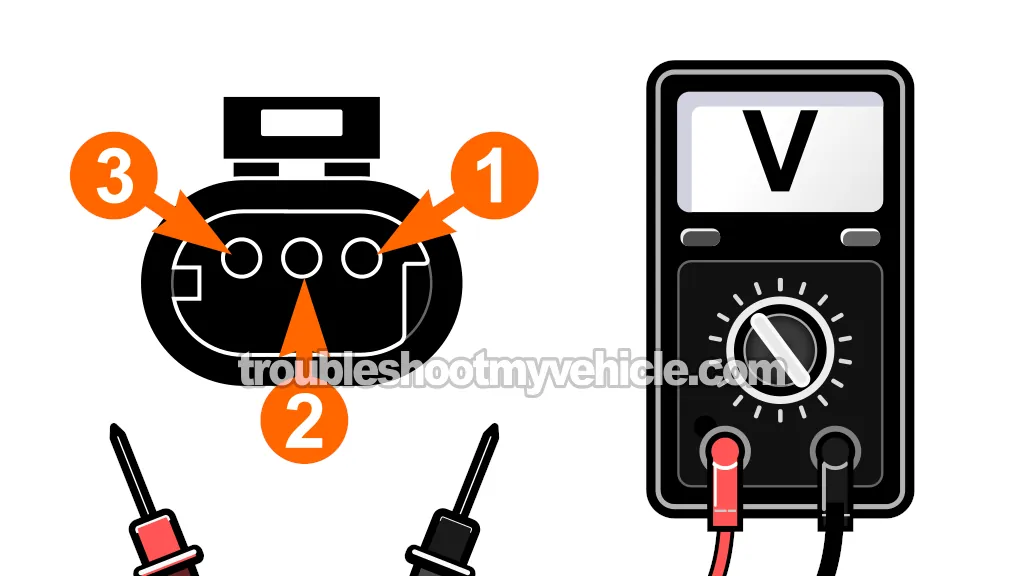

TEST 2: Making Sure The CKP Sensor Is Getting 8 Volts

If you've reached this point, you've confirmed that the CKP sensor isn't generating an ON/OFF voltage pulse. Our next step is to make sure that the CKP sensor is getting power and this power is in the form of 8 Volts DC.

The wire that delivers these 8 Volts to the CKP sensor is the orange (ORG) wire of the sensor's 3-wire connector.

To check for the presence of these 8 Volts in the ORG wire, we're going to do a simple multimeter voltage test on it.

Let's get started:

- 1

Place your multimeter in Volts DC mode.

- 2

Connect the black multimeter test lead directly on the battery negative (-) terminal.

- 3

Disconnect the crankshaft positions sensor from its electrical connector.

- 4

Gently probe the connector terminal labeled with the number 1 with the red multimeter test lead and an appropriate tool..

NOTE: Terminal number 1 should connect to the ORG wire. - 5

When everything is set up, have your helper turn the key to the RUN position but but not crank the engine.

- 6

Your multimeter should register 7 to 8 Volts DC.

OK, let's interpret your test result:

CASE 1: The multimeter registered 7 to 8 Volts DC. This let's you know that the CKP sensor is getting the voltage it needs to function.

The next and last step is to make sure that the CKP sensor is getting Ground. For this test go to: TEST 3: Making Sure The CKP Sensor Is Getting Ground.

CASE 2: The multimeter DID NOT register 7 to 8 Volts DC when the key was turned On. Recheck your connections and try the test again.

If the multimeter still doesn't register 7 to 8 Volts, you've found the reason why the CKP sensor is not generating a voltage signal in TEST 1.

Although it's beyond the scope of this tutorial, your next step is to find the reason why these 8 Volts are missing and restore them. The most likely reasons for this missing voltage is:

- Open-circuit problem in the wire between the CKP sensor connector and the fuel injection computer.

- The CKP sensor connector is bad.

- The fuel injection computer is bad (very rare).

Solving the issue that is causing these missing 7 to 8 Volts will solve the no-start condition of the engine.

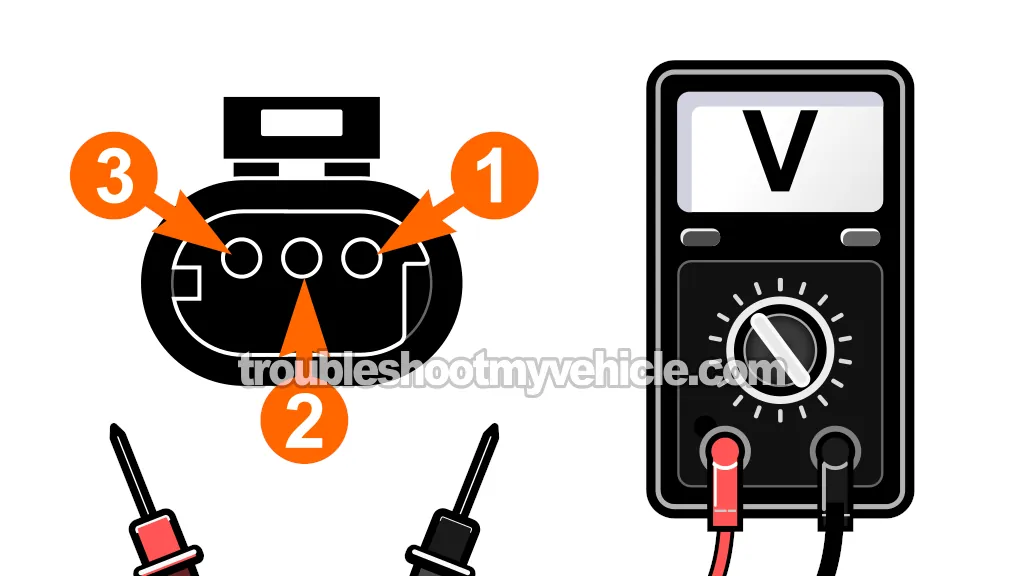

TEST 3: Making Sure The CKP Sensor Is Getting Ground

For our final test, we're gonna make sure that the CKP sensor is getting Ground. This Ground is supplied by the fuel injection computer and is delivered to the CKP sensor by the black with light blue (BLK/LT BLU) wire of the sensor's 3-wire connector.

To check for the presence of Ground in the BLK/LT BLU wire, we're going to do a simple multimeter voltage test.

IMPORTANT: You got to be very careful not to short this wire to battery voltage, or the PCM will get damaged. Also, for the most accurate test result, don't use a test light to verify this voltage, use a multimeter.

OK, these are the test steps:

- 1

Place your multimeter in Volts DC mode.

- 2

Connect the red multimeter test lead to the battery positive (+) terminal.

- 3

Disconnect the crankshaft positions sensor from its electrical connector.

- 3

Gently probe the connector terminal labeled with the number 2 with the black multimeter test lead and an appropriate tool.

NOTE: Terminal number 2 should connect to the BLK/LT BLU wire. - 5

When everything is set up, have your helper turn the key to the RUN position but not crank the engine.

- 6

Your multimeter should register 10 to 12 Volts DC.

Lets see what your test result means:

CASE 1: The multimeter registered 10 to 12 Volts DC. This tells you the CKP sensor is getting Ground.

You can conclude that the crankshaft position (CKP) sensor is bad if you have:

- Confirmed the CKP is not generating an ON/OFF voltage signal (TEST 1).

- Confirmed the CKP is getting 8 Volts DC (TEST 2).

- Confirmed in this test step the CKP sensor is getting Ground.

CASE 2: The multimeter DID NOT register 10 to 12 Volts DC. Recheck your connections and try the test again.

If the multimeter still doesn't register 10 to 12 Volts, you've found the reason why the CKP sensor is not generating a voltage signal in TEST 1.

Although it's beyond the scope of this tutorial, your next step is to find the reason why this Ground is missing and restore it. The most likely reasons for this missing Ground are:

- Open-circuit problem in the wire between the CKP sensor connector and the fuel injection computer.

- The CKP sensor connector is bad.

- The fuel injection computer is bad (very rare).

CKP Sensor Air Gap Calibration (Paper Spacer)

When the CKP sensor was new and before it was installed, it had a paper spacer. The purpose of this spacer is to keep a small space (an air gap) between the sensor and the flywheel reluctor ring.

This air gap is critical since it stops the flywheel from hitting the sensor, which would break it. Following the sensor's installation and the engine's initial start-up, the spinning flywheel trims away the paper spacer (but the air gap remains in place).

If you ever take out the CKP sensor after the engine has been running, you need to put a new spacer on it before installing it. Without the spacer, the sensor will touch the flywheel when the engine starts, and it'll get destroyed.

Thankfully, you can make your own spacer with a notecard by folding it to get the right thickness. The paper spacer's thickness should be between 0.030 to 0.034 inches. I've usually made mine from either a folded notecard (cut into a circle) or a matchbook cover, and then used bearing grease to attach it to the sensor while installing it.

If this info saved the day, buy me a beer!