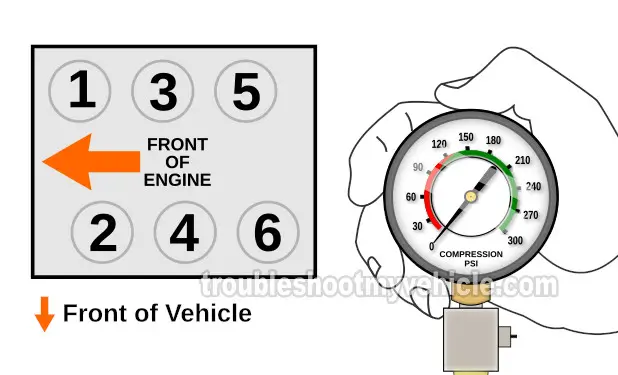

TEST 3: Engine Compression Test

A head gasket can fail between two adjacent cylinders, leading to a situation where both cylinders experience a loss of compression.

To explain this a bit more, when the head gasket fails between two side-by-side cylinders, a pathway is created for the compression to escape from one cylinder to the other instead of being properly contained. This results in a complete loss of compression in both cylinders.

This type of failure shows up as a misfire in both affected cylinders, a noticeable loss of engine power, and a rough running engine (since it's only running on four cylinders instead of six).

While this type of head gasket failure doesn't happen all the time, it's common enough that we need to check for it. A simple way to do this is by performing an engine compression test. In this section, I'll guide you through how to do the compression test.

NOTE: You can find the engine compression test and how to interpret its results explained in more detail here: How To Test Engine Compression (1987-2000 3.0L V6 Chrysler, Dodge, Plymouth).

OK, these are the test steps:

- 1

Disconnect the ignition coil from its electrical connectors. This is will disable the ignition system and is an important safety precaution.

- 2

Disconnect all spark plug wires (from their spark plugs).

- 3

Remove all of the spark plugs.

- 4

Thread in the compression tester by hand, on the first spark plug hole you're gonna' start with.

Do not use any tools to tighten the compression tester. Hand tightening the compression tester is more than enough to get the proper results. - 5

Have a helper crank the engine as you observe the compression tester.

- 6

When the gauge's needle stops climbing, have your assistant stop cranking the engine.

- 7

Write down the reading and what cylinder it belongs to on a piece of paper (you can use the illustration above to help you identify the cylinder).

- 8

Remove the compression tester and repeat the above steps in the remaining cylinders.

Let's examine what your results mean:

CASE 1: All cylinder compression readings where normal. This is the correct test result and it confirms that the head gasket isn't burned at a spot between two side-by-side cylinders.

If you still suspect a blown head gasket, go to: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

CASE 2: Two side by side cylinders had 0 PSI compression. This test result confirms that the head gasket is burned at the point between those two cylinders. Replace the head gasket.

TEST 4: Using A Chemical Block Tester (Combustion Leak Tester)

In some cases, a head gasket failure can be a challenge to diagnose because it doesn't present the typical symptoms like the oil turning a milky-white color, coolant being pushed out of the radiator when cranking the engine, or loss of compression.

If the only thing happening is the engine overheating soon after you start it, without any apparent reason why, this could actually be a less obvious sign of a head gasket failure.

In these cases, a chemical block test (also known as a combustion leak test) is the only way to confirm that the overheating issue is caused by a blown head gasket. The test is designed to detect the presence of combustion gases in the cooling system caused by a head gasket that is just beginning to fail.

This is how the combustion leak detector test (block test) works:

- The combustion leak detector tester is filled with a blue liquid chemical (see photo above).

- The radiator cap is removed (you may have to drain some of the coolant in the radiator since this tool needs to ‘gulp’ some of the air inside the radiator).

- The engine is started.

- The tester is then placed on the open radiator neck.

- The rubber bellow is then squeezed to suck in the air up through the two fluid-filled chambers. As the air bubbles up through the fluid, it will cause a chemical reaction.

- If the blue chemical turns yellow (for gasoline engines), then combustion gases are entering the radiator. This in turn confirms a blown head gasket, a cracked block, or a cracked cylinder head issue.

- If the blue chemical doesn't change color, then you can conclude that you don't have a blown head gasket, a cracked block, or cracked cylinder head issue.

You can shop for a block tester here:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

Frequently Asked Questions

Should I Replace Both Head Gaskets?

The correct approach is to replace both head gaskets, even if only one has blown. The reason is that when the engine overheated, the entire engine was subjected to extreme heat, not just the area around the failed head gasket. This means the second head gasket, although it hasn't failed yet, could have been weakened by the same heat stress.

By replacing both gaskets at the same time, you're making sure that both cylinder banks are in good shape. In the long-run, this will save you both time and money, since it reduces the likelihood of the other head gasket failing soon after, which would mean having to do the repair all over again.

Should I resurface the cylinder heads?

Resurfacing the cylinder heads at an automotive machine shop is crucial, especially when dealing with a head gasket issue caused by an overheating engine. Here's a bit more detail:

- Purpose of Resurfacing Cylinder Heads:

- When a head gasket fails, especially due to overheating, it can cause the cylinder head to warp or become uneven. This warping can prevent a proper seal with the new head gasket.

- Resurfacing involves machining or grinding the bottom surface of the cylinder head (the part that mates with the engine block) to ensure it's perfectly flat and smooth.

- Checking for Warpage:

- Before resurfacing, a technician will check the cylinder head for warpage using a straightedge and feeler gauge. This determines if resurfacing is necessary and to what extent.

- Should You Resurface Both Heads?:

- If one head gasket has failed and you're replacing both (as discussed earlier), it's wise to inspect and potentially resurface both cylinder heads. Even if the second head doesn't show immediate signs of warpage, the same stresses that caused the first gasket to fail (like overheating) could have affected it.

- Resurfacing both heads ensures they provide a good seal with the new head gaskets and helps prevent future gasket failures.

- Consideration of Engine Specifications:

- It's important to note that cylinder heads can only be resurfaced to a certain extent. Removing too much material can affect the engine's compression ratio and valve timing. The folks at the machine shop will know how much material can be safely removed based on your engine's specifications.

Resurfacing the cylinder heads is a crucial step in replacing the head gaskets, especially if the engine overheated. It ensures that the new gaskets seal correctly and will keep the engine running reliably. If you're already putting in the effort to replace both head gaskets, it's definitely wise to have both cylinder heads checked and resurfaced if necessary to ensure that you won't have to redo the job later.

If this info saved the day, buy me a beer!