Testing the manifold absolute pressure (MAP) sensor on your 1995 2.0L Dodge Stratus isn't difficult. All it takes is 3 simple tests.

These tests can be done with a multimeter (no need for an expensive scan tool) and will tell you if the MAP sensor is bad or not.

I'll also explain some of the symptoms you might experience with a bad MAP sensor and show you where you can buy a replacement.

Contents of this tutorial:

- What Does The MAP Sensor Do?

- Symptoms Of A Bad MAP Sensor.

- MAP Sensor Circuit Descriptions And Connector Pinout.

- Where To Buy The MAP Sensor And Save.

- TEST 1: Testing The MAP Sensor Voltage Signal.

- TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.

- TEST 3: Making Sure The MAP Sensor Is Getting Ground.

ES ![]() You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP De 3 Cables (1995 2.0L Dodge Stratus) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar El Sensor MAP De 3 Cables (1995 2.0L Dodge Stratus) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 2.0L Dodge Stratus: 1995.

NOTE: This tutorial applies only to the 3-wire MAP sensor. If your Dodge Stratus or Plymouth Breeze comes equipped with a 4-wire MAP sensor, see this tutorial:

What Does The MAP Sensor Do?

The MAP sensor, or Manifold Absolute Pressure sensor, is a device located on the intake manifold. It's job is to send intake manifold pressure readings to the engine's computer.

With the intake manifold pressure readings, the computer can figure out how much air is coming into the engine. This info is vital for the computer to decide how much fuel to inject into the cylinders for the engine to run properly.

To be a bit more specific:

- When you press the gas pedal, the throttle opens, letting more air into the manifold, and engine RPM increases.

- The vacuum pressure inside the intake manifold decreases (meaning the absolute pressure gets closer to atmospheric pressure).

- The MAP sensor sends this new info to the computer.

- The computer now knows more air is entering the engine and adjusts the amount of fuel to inject into the engine cylinders accordingly.

- When you release the gas pedal, the throttle closes, letting less air into the manifold, and engine RPM decreases.

- The vacuum pressure inside the intake manifold increases (meaning the absolute pressure becomes lower than atmospheric pressure).

- The MAP sensor sends this new info to the computer.

- The computer now knows less air is entering the engine and adjusts the amount of fuel to inject into the engine cylinders accordingly.

Symptoms Of A Bad MAP Sensor

When the MAP sensor fails, your Stratus's fuel injection computer won't be able to fine-tune the air/fuel mixture the engine needs to run optimally, causing several problems. Here are some common symptoms:

- Poor Fuel Economy: The computer will be injecting too much fuel for the amount of air entering the engine, and you'll get less miles per gallon of fuel.

- Rough Idle: The engine may shake or vibrate when you stop, like at a red light.

- Engine Hesitation: When you step on the gas, the car may hesitate or jerk before picking up speed.

- Stalling: In severe cases, the car might stall out, especially when idling or at low speeds.

- Check Engine Light: This malfunction indicator light will come on to warn you that something's wrong.

- MAP Sensor Trouble Codes: You'll have one of the following trouble codes stored in the computer's memory:

- P0105: MAP Circuit Malfunction

- P0106: MAP/Barometric Pressure Circuit Range/Performance Problem

- P0107: MAP Circuit Low Input

- P0108: MAP Circuit High Input

MAP Sensor Circuit Descriptions And Connector Pinout

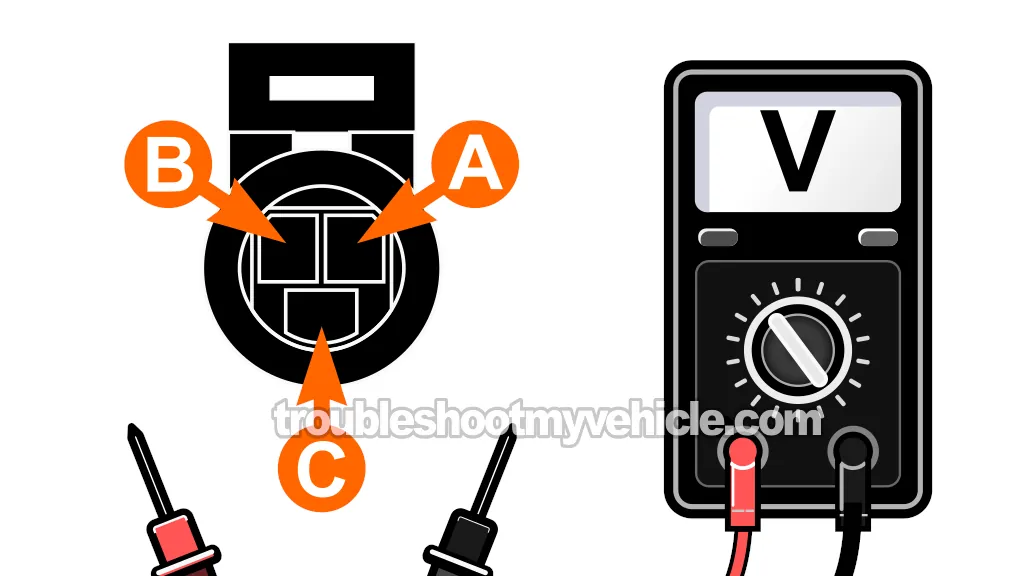

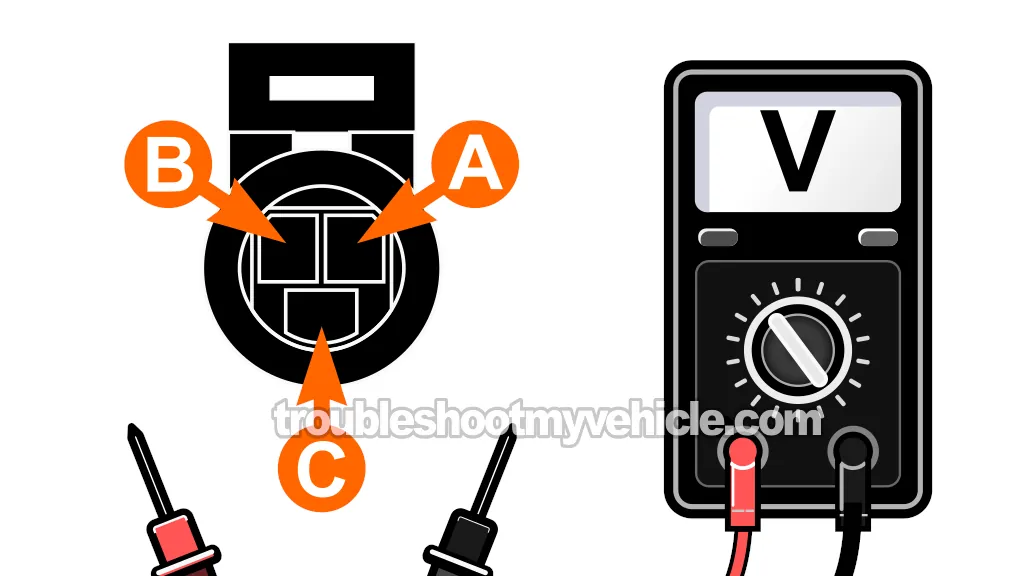

The MAP sensor is 3-wire type sensor. This means that it has a power wire, a Ground wire and a signal wire. The table below has a brief description of each:

| 1995 3-Wire MAP Sensor Circuits | ||

|---|---|---|

| Terminal | Wire | Description |

| A | Black with light blue stripe (BLK/LT BLU) | Ground |

| B | Violet with white stripe (VIO/WHT) | 5 Volts |

| C | Dark green with red stripe (DK GRN/RED) | MAP Signal |

To successfully test the manifold absolute pressure (MAP) sensor, it's important to know that:

- As vacuum is applied to the MAP sensor, its voltage signal decreases.

- As this vacuum is released, its voltage signal increases.

To get the most accurate test result, you'll apply vacuum to it with a vacuum pump. If you don't have one, don't worry. You can use your mouth.

Where To Buy The MAP Sensor And Save

The MAP sensor isn't an expensive engine management component, but it never hurts to save a few bucks and so with that in mind I think that the following links will help you to comparison shop for it and maybe even save a few bucks:

- Ramco Automotive (RA-MS1021) Manifold Absolute Pressure Sensor (at: amazon.com)

- Standard Motor Products AS41T Manifold Absolute Pressure Sensor (at: amazon.com)

TEST 1: Testing The MAP Sensor Voltage Signal

The first thing we'll do is test the MAP sensor's signal voltage using a multimeter. We're looking to see how the MAP signal responds when we apply vacuum manually.

To perform this test, we'll use a vacuum pump. Generally, the signal decreases with increased vacuum and increases as the vacuum is released.

We'll connect the multimeter to the wire that connects to the female terminal labeled with the letter C (in the illustration above). This wire is the dark green with red stripe (DK GRN/RED) wire of the connector.

If you don't have a multimeter and need to buy one, check out my recommendations here: Buying A Digital Multimeter For Automotive Diagnostic Testing (at: easyautodiagnostics.com).

IMPORTANT: The MAP sensor needs to stay connected to its electrical connector for this test to work. You'll need to use a back-probe or a wire-piercing probe to measure the MAP signal voltage. To see what a wire-piercing probe looks like, go here: Wire Piercing Probe.

Let's get started:

- 1

Remove the MAP sensor from its place on the intake manifold.

NOTE: If you had to disconnect the MAP sensor to remove it, reconnect it now to its electrical connector. - 2

Connect your vacuum pump to the MAP sensor's vacuum inlet port.

- 3

Set your multimeter's selector to Volts DC mode.

- 4

Connect the red multimeter test lead to the DK GRN/RED wire of the MAP sensor's connector.

IMPORTANT: Remember, the MAP sensor must remain connected to its 3 wire connector. - 5

Ground the black multimeter test lead directly on the battery negative (-) terminal.

- 6

When everything is ready, turn the key to the ON position but don't start the engine. This will power up the MAP sensor and you should see a reading of 4.7 Volts DC on your multimeter.

- 7

Now, apply vacuum to the MAP sensor with the vacuum pump (or your mouth). The voltage signal value should decrease.

- 8

Release the vacuum. Once released, your multimeter should show the original voltage value.

- 9

Apply and release vacuum to the MAP several times. Each time the voltage should decrease/increase as you apply/release vacuum.

Let's find out what your test results mean:

CASE 1: The MAP voltage signal decreased and increased as you applied and released vacuum. This is the correct and expected test result and lets you know that the MAP sensor on your 2.0L Dodge Stratus is not defective.

This test result also let you know that the MAP sensor is getting power and Ground from the fuel injection computer.

CASE 2: The MAP voltage signal DID NOT increase (and/or decrease) as you applied and released vacuum. In most cases, this test result is enough to confirm that the MAP sensor is defective and that it needs to be replaced.

But to be sure that the MAP sensor is defective, we need to make sure that it's getting power and Ground. For the first of these two tests, go to: TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.

CASE 3: The multimeter DID NOT register any voltage. In most cases, this test result is enough to confirm that the MAP sensor is defective and that it needs to be replaced.

But to be sure that the MAP sensor is defective, we need to make sure that it's getting power and Ground. For the first of these two tests, go to: TEST 2: Making Sure The MAP Sensor Is Getting 5 Volts.