TEST 2: Checking The Continuity Of The Bat (+) Cable

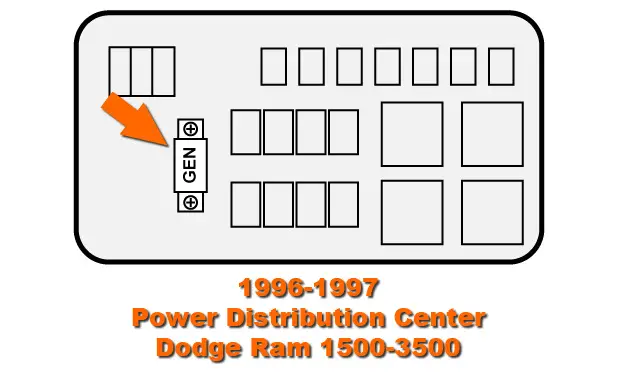

The current that your Dodge Ram pickup's alternator produces reaches the battery across a 120 (or 140) amp mega fuse that's located in the under-hood fuse/relay box.

This under-hood fuse/relay box is known as the power distribution center and to help you locate this fuse, I have highlighted this mega fuse with an orange colored arrow in the illustrations in the image viewer (see images 2 thru' 4).

On the 1994-1997 Dodge Ram pickups, this mega fuse is a 120 amp fuse. On the 1998 Dodge Ram pickups, this mega fuse is a 140 amp fuse.

NOTE: The battery negative (-) terminal must be disconnected from the battery negative (-) post to perform this continuity test.

This is what you'll need to do:

- 1

Disconnect the battery negative (-) cable terminal from the battery negative (-) post. The positive cable remains connected.

IMPORTANT: Don't continue to the next step without first disconnecting the negative cable from the negative battery post. - 2

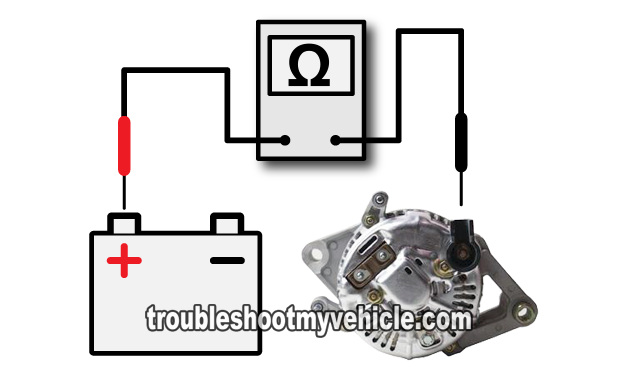

After disconnecting the battery negative (-) cable, turn on your multimeter and select Ohms mode.

IMPORTANT: The engine must be cold to perform this test, or you run the risk of getting burned by the engine's hot surfaces! - 3

Your Dodge pickup's alternator has only one big wire attached to it. This wire is attached with a nut. So, place your multimeter's RED test lead on the stud to which this wire is connected to.

The arrow in the photo points to this stud. - 4

With the black multimeter test lead, probe the center of the battery positive (+) post on your Dodge pickup's battery.

- 5

You'll get one of two results.

1.) If the mega fuse, protecting this circuit, is blown, your multimeter will indicate a reading of OL (which means over limit). In other words, there will be NO continuity.

2.) If the mega fuse is OK and not blown, your multimeter will register an Ohms reading of 0.5 Ohms or less. In other words, there will be continuity.

Let's take a look at what your results mean:

CASE 1: Your multimeter registered continuity. This continuity test result tells you that the 120 (or 140) amp mega fuse is NOT blown.

If the alternator is still not charging the battery (let‘s say you've already replaced the alternator and it didn't solve the problem), take a look at: Alternator Is New But It Still Doesn't Charge The Battery.

CASE 2: Your multimeter DID NOT register continuity. This result tells you that the 120 (or 140) amp mega fuse is blown.

Your next step is to check and replace the mega fuse and retest. Replacing this mega fuse (if blown) should solve your No Charge condition. You'll have to investigate the reason the fuse blew, since they don't get blown for no particular reason.

TEST 3: Part 1 -Alternator Is New But It Still Doesn't Charge The Battery

The alternator on your Dodge Ram pickup (except diesel) is computer controlled. To be a bit more specific, the alternator's voltage regulator is located inside the PCM.

Besides the voltage regulator, the PCM also uses a Battery Temperature Sensor (BTS) to control the alternator and this bad boy (the BTS) is also part of the internal circuitry of the PCM. In other words, this sensor is also part of the PCM. Its job is to sense battery temperature so that the PCM can adjust the alternator's charging rate.

So, if you have already replaced the alternator with a new one, and you're still experiencing a no charge condition, then there's a good chance that the PCM could be bad.

Your first step should be to check for alternator trouble codes, since the PCM sets specific alternator diagnostic trouble codes when a fault occurs:

- P0622: Generator Field Not Switching Properly.

- P1492: Battery Temperature Sensor Voltage Too High.

- P1493: Battery Temperature Sensor Voltage Too Low.

- P1594: Charging System Voltage Too High.

- P1682: Charging System Voltage Too Low.

The one component of the two (inside the PCM) that we can test is the electronic voltage regulator (EVR) and in the next section, I'll explain how.

TEST 3: Part 2 -Testing The Voltage Regulator Inside The PCM

The electronic voltage regulator, EVR for short and located inside your pickup's PCM, controls the current/voltage output of the alternator by grounding the GEN FLD circuit. Here are some more specifics:

One: It's connected in series with the alternator and Ground (making it possible to tap into the circuit and test the EVR).

Two: The electronic voltage regulator (EVR) controls the alternators voltage/amperage output by cycling the Ground on and off very fast (this is called pulse-width modulation). By the way, another component that works on this very same principle is a fuel injector where the computer controls its ‘open’ time my opening and closing its Ground path (pulse with modulation).

In the case of your pickup's alternator, this ‘open’ time (caused by the cycling of the Ground path by the EVR) is what increases or decreases its voltage and amperage output.

Thankfully, you and I can verify if this is occurring (the pulse-width modulation of the Ground circuit by the EVR) by connecting your multimeter to the GEN FLD wire, of the alternator's harness connector and doing a simple multimeter voltage test with the engine running.

Now, while testing this pulse-width modulation with a multimeter, you're not gonna' see the voltage reading turn on and off because the cycling of the circuit is done very fast and the multimeter is not capable of showing it (only an oscilloscope can) but you'll see an average of this cycling on and off, which the multimeter will translate into a number.

NOTE: You need to perform this test on a cold engine, or you run the risk of getting burned by a hot engine while connecting your multimeter to the GEN FLD wire of the alternator's harness connector (if the engine has been running for any length of time).

This is what you need to do:

- 1

Disconnect the battery negative (-) cable terminal from the battery negative (-) post. The positive cable remains connected.

- 2

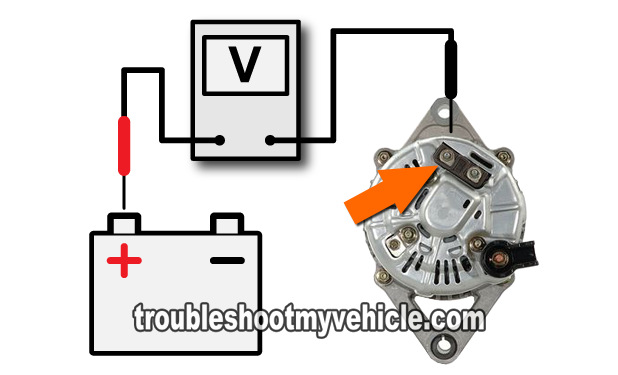

Connect the multimeter's black test lead to generator field (GEN FLD) wire of the alternator's 2-wire connector.

This is usually a DK GRN (dark green) wire of the alternator's harness connector.

Since the alternator must remain connected to its harness connector, you'll need to use a wire piercing probe to connect your multimeter's black lead to this wire (see: Wire Piercing Probe). - 3

Set your multimeter to Volts DC mode and connect the red multimeter test lead to the battery's positive (+) post.

At this point, reconnect the battery negative (-) cable to the battery negative (-) post.

Before you continue to the next step, make sure that your multimeter test leads/wires are not gonna' get tangled with the engine's serpentine belt. - 4

Start the engine and notice the voltage output of the multimeter.

Once the engine idle stabilizes, note the voltage number your multimeter is displaying. You many notice that this number fluctuates a little and this is normal.

NOTE: There's no specific number to give you or that you should expect because the EVR's pulse-width modulation of your specific pickup is unique to the actual operating conditions and charge level of your pickup's battery. - 5

Have a helper turn on all accessories possible like the headlights, rear window defroster, A/C, radio, etc.

Your multimeter should now show an increase in the voltage number from the original values it showed you when the engine was just idling with everything off. - 6

Have your helper turn off all the things he (or she) turned on in step 4.

Your multimeter should now show a decrease in the voltage number from the original values it showed you when the engine was just idling with everything off.

NOTE: Keep in mind that if the EVR is good and doing its job, the voltage value your multimeter registers will fluctuate as it increases and decreases and this is normal. In other words, don't expect the voltage number to increase and decrease in a steady linear manner. The important thing to see here is that the voltage values increase and decrease as you apply or remove the electrical loads created by the headlights, rear window defroster, etc.

Let's take a look at what your test results mean:

CASE 1: Your multimeter registered an increasing/decreasing voltage as you applied and removed the electrical loads. This result tells you that the electronic voltage regulator (EVR) inside the PCM is working and trying to control the alternator's amperage/voltage output.

CASE 2: Your multimeter DID NOT an increasing/decreasing voltage as you applied and removed the electrical loads. This result usually tells you that the EVR is bad and that the PCM needs to be replaced.

Before you run out and replace the PCM, you need to:

- Have your local auto parts store check the alternator on their bench-testing machine.

- NOTE: New or rebuilt alternators can be defective right out of the box!

- Check that there isn't an ‘open’ in the GEN FLD circuit between the PCM and the alternator's harness connector.

- Check all of the PCM's Ground circuits by doing a voltage drop test on them and repairing any corrosion issues that the voltage drop test finds.

- That the battery's terminals and posts are corrosion free.

Now, if the above is beyond your diagnostic skills, don't hesitate to get a professional tech's opinion and/or advice.

More Dodge 3.9L, 5.2L, 5.9L Tutorials

I've been adding a lot of 3.9L V6 and 5.2L/5.9L V8 tutorials for both the full-size Dodge Ram pickups and vans. You can find all the new tutorials in these new indexes:

3.9L V6 Pickups And Vans:

5.2L/5.9L V8 Pickups And Vans:

OLD INDEX: This is the old index (that I'm no longer adding tutorials to):

Here's a sample of the tutorials you'll find in the old index:

- How To Test A No Start Condition (Dodge 3.9L, 5.2L, 5.9L).

- How To Test The Crank Sensor (1994-1996 3.9L, 5.2L, 5.9L Chrysler).

- How Can I Tell If My Automatic Transmission Needs An Overhaul?

- How To Test The MAP Sensor (P0107, P0108) (Dodge 3.9L, 5.2L, 5.9L).

- How To Diagnose Misfire Codes (Dodge 3.9L, 5.2L, 5.9L).

If this info saved the day, buy me a beer!