Sometimes, even if the engine is misfiring, the fuel injection computer wont' give you a specific cylinder misfire trouble code. This can complicate diagnosing the root cause of the misfire.

In these cases, performing a manual cylinder balance test will help you identify the 'dead' cylinder and save you a lot of time and frustration. Besides being an easy test to perform, you don't need any expensive diagnostic equipment.

Contents of this tutorial:

You can find this tutorial in Spanish here: Cómo Hacer La Prueba Balance De Cilindros (1995-2005 2.0L SOHC Neon) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Hacer La Prueba Balance De Cilindros (1995-2005 2.0L SOHC Neon) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

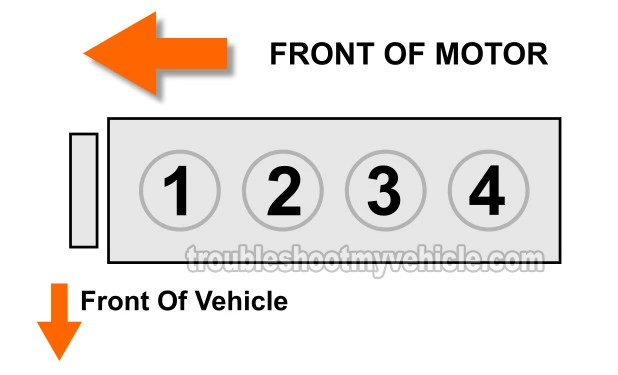

- 2.0L Dodge Neon: 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002,2003, 2004, 2005.

- 2.0L Plymouth Neon: 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002,2003, 2004, 2005.

Manual Cylinder Balance Test

In a nutshell, the manual cylinder balance test is done by disconnecting one fuel injector at a time while your Neon's engine is running.

When you disconnect the fuel injector from a healthy ('live') cylinder, you'll notice a drop in the engine RPMs and the engine will run a bit more rough. Once you reconnect the fuel injector, the engine idle RPM return back to whatever it was before unplugging the fuel injector.

If the cylinder is already having issues, disconnecting its injector won't affect the engine's RPMs or anything else.

To get the most accurate result from your test, you can attach a vacuum gauge to a vacuum hose on the engine. You'll observe whether the gauge needle moves when disconnecting or connecting injectors. Now, if you don't have one, don't worry, this step isn't essential, and the test can be done without it.

CAUTION: Take all necessary safety precautions while working around a running engine.

OK, here's what you need to do:

- 1

Remove any air intake component from the throttle body (if necessary) so you can access the fuel injectors.

- 2

Attach a vacuum gauge to any available vacuum hose.

You can use a plastic 'T' connector to attach your vacuum gauge to the fuel pressure regulator's vacuum supply hose (if your Neon comes equipped one on the fuel injector rail).

NOTE: Remember, using a vacuum gauge is not absolutely necessary. - 3

Crank and start the engine.

- 4

Disconnect and reconnect one fuel injector at a time.

When you disconnect the fuel injector, you should hear and feel a drop in engine idle (RPMs). If you also have a vacuum gauge connected, you'll see the needle on the gauge drop.

If the cylinder was 'dead' to begin with for any reason (lack of spark, low compression, etc.), you won't hear/feel a drop in engine idle (RPMs). - 5

Repeat the test on the same cylinder.

You can repeat this test as many times as you need to be completely sure of your test result. - 6

Reconnect the injector and repeat steps 4 to 6 on the remaining injectors.

Let's analyze the result of your cylinder balance test:

CASE 1: Disconnecting the fuel injector caused a drop in the engine RPMs. This tells you that the specific cylinder you tested is fine and is not the cause of the cylinder failure.

More specifically, this result in this particular cylinder lets you know that the fuel injector, spark plug, and spark plug wire are all OK.

CASE 2: Disconnecting the fuel injector did NOT cause a drop in RPMs. This tells you that the specific cylinder you tested is 'dead'.

The cylinder could be failing for various reasons. For example:

- Bad spark plug (broken, extremely worn, with carbon tracks, etc.).

- Bad spark plug boots.

- Bad ignition coil.

- Low engine compression.

- Bad or clogged fuel injector.

The list of possible failures is a bit extensive, but the most important thing you've already achieved is identifying the misfiring cylinder. This narrows down and focuses your efforts on finding the precise cause of the problem.

I've written several tutorials that will help you further troubleshoot the misfiring cylinder, you can find them here: Tutorials To Help You Find The Cause Of Cylinder Misfire.

NOTE: In some cases, the engine idles so rough that a manual cylinder balance test can't single out a misfiring cylinder. If this is the case in your particular situation, you can conclude that the issue is affecting all four cylinders, not just one.

A possible cause behind a rough idle affecting all cylinders equally could be a leak in the intake manifold affecting the air/fuel mixture. Other possible issues:

- Fuel pressure regulator leaking fuel into its vacuum hose/line (if equipped with one on the fuel injector rail).

- Stuck open EGR valve (if applicable).

- Fuel pump supplying insufficient fuel volume/pressure.

- Large vacuum leak.

- Low engine compression in all cylinders.

Tutorials To Help You Find The Cause Of Cylinder Misfire

After completing the manual cylinder balance test and discovering a cylinder that's not functioning correctly, you might be wondering: What do I do now?

The next step is to troubleshoot the cause behind the cylinder misfire. This involves identifying which of the 3 basic things (that the cylinder needs to operate) is missing. These 3 things are: 1.) Spark, 2.) Fuel, 3.) Air (compression).

To further assist you in your diagnosis, here are some more specific details:

- Things that can cause a lack of spark to the cylinder:

- Defective ignition coil.

- Defective spark plug.

- Defective spark plug wire.

- Engine oil leaking onto the spark plugs from the valve cover.

- Things that can cause a lack of fuel to the cylinder:

- Bad fuel injector.

- Clogged fuel injector.

- Malfunctioning fuel injection computer that's not pulsing (activating) the injector (very rare).

- An electrical issue in the injector connector wiring.

- Things that can cause a lack of air to the cylinder:

- Low engine compression.

The list above may make diagnosing the cause of a 'dead' cylinder seem difficult, but with a good diagnostic strategy, you'll be able to find the exact cause of the failure.

Here are my suggestions (and the diagnostic strategy I use):

- First, test the ignition system.

- The ignition system is often the culprit behind most cylinder misfires.

- You can find a detailed tutorial on how to test the ignition coils here: How To Test The Ignition Coil Pack (Chrysler 2.0L, 2.4L) (at: easyautodiagnostics.com).

- Test the fuel injectors second.

- After ruling out the ignition system as the cause of the misfire, the next step is to make sure the fuel injector isn't internally damaged.

- How To Test The Fuel Injectors (1996-1997 2.0L Neon)

- How To Test The Fuel Injectors (1998-2000 2.0L SOHC Neon)

- How To Test The Fuel Injectors (2001-2003 2.0L SOHC Neon)

- How To Test The Fuel Injectors (2004-2005 2.0L SOHC Neon)

- Test the engine compression third.

- After ensuring that the ignition system is providing spark and the fuel injector is injecting fuel into the 'dead' cylinder, the next step would be to check the compression of that cylinder.

- How To Test The Engine Compression (Chrysler 2.0L, 2.4L)

You can modify the list of tests to adapt it to your particular diagnostic needs (since there really isn't a specific and unique way to diagnose a cylinder misfire).

If this info saved the day, buy me a beer!