The fuel injectors on your Dodge/Plymouth Neon are electromechanical valves, opening and closing thousands of times to spray (atomize) gasoline into their cylinder. This repetitive process will eventually wear them out.

Generally, they suffer some sort of internal electrical problem and stop injecting fuel into the cylinder they're connected to. As a result, the engine ends up having performance issues.

If you suspect one of the injectors is bad or clogged, this tutorial will walk you through how to check it and figure out if it's good or bad. And the best part is you don't need expensive tools for the test.

NOTE: This tutorial only applies to the 2.0L SOHC engine (Single Overhead Camshaft).

Content of this tutorial:

You can find this tutorial in Spanish here: Cómo Probar Los Inyectores De Combustible (2004-2005 2.0L SOHC Neon) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar Los Inyectores De Combustible (2004-2005 2.0L SOHC Neon) (at: autotecnico-online.com).

APLICA A: Este tutorial aplica a los siguientes vehículos:

- 2.0L Dodge Neon: 2004, 2005.

- 2.0L Plymouth Neon: 2004, 2005.

Symptoms Of A Bad Fuel Injector

Fuel injectors commonly suffer from one of two problems. One is an internal issue resulting in a short circuit or open circuit in the internal winding, which stops them from injecting fuel.

The second issue, and probably the more common one, is getting clogged, which prevents them from properly atomizing fuel. Both types of issues lead to a misfiring cylinder.

These are the most common symptoms you'll see when one fails:

- Rough idle.

- Lack of power.

- The engine hesitates when you accelerate under load.

- Cylinder misfire trouble codes:

- P0300: Random Cylinder Misfire.

- P0301: Misfire In Cylinder #1.

- P0302: Misfire In Cylinder #2.

- P0303: Misfire In Cylinder #3.

- P0304: Misfire In Cylinder #4.

Whether the injector has an internal electrical issue or is clogged, this tutorial has got you covered with the info you need to find out exactly what's going on. No more throwing money at guesses, you'll know exactly what's wrong. If the injector resistance test doesn't identify the issue, this section will:

Checking The Resistance Of The Fuel Injectors

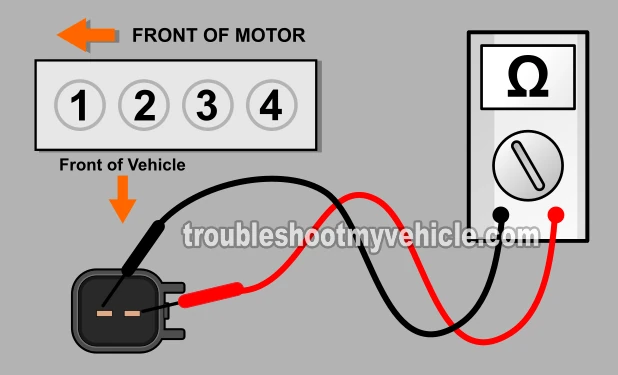

To find out if the injector has suffered an internal electrical problem, we're going to check its internal resistance with a multimeter set to Ohms mode.

Generally, a good injector will have an internal resistance of 10 to 16 Ohms. Anything else means it's probably bad.

NOTE: It's important to note that when performing this test, your Neon should be at room temperature; that is, the engine should be cold.

Let's get started:

- 1

Disconnect the fuel injectors from their electrical connectors.

NOTE: To identify which cylinder the fuel injector belongs to, see the illustration above with the cylinder numbers for the 2.0L Neon. - 2

Set the multimeter to Ohms (Ω) mode.

- 3

Measure the fuel injector's resistance across its two male terminals with the multimeter probes (see the illustration above).

- 4

Record the resistance value that your multimeter shows for the specific fuel injector you're testing.

The illustration above will help you identify the cylinder number to which the fuel injector belongs. - 5

Repeat steps 1 to 3 for the remaining fuel injectors.

NOTE: The resistance specification for the 2.0L Neon is: 10 to 16 Ohms.

Let's find out what your specific multimeter test results mean:

CASE 1: The resistance of each injector is within the specified values. This is the correct test result and confirms that they have no internal short-circuit or open-circuit issues.

If you suspect a clogged fuel injector (something the resistance test can't detect), go to: How To Find The Bad Or Clogged Fuel Injector.

CASE 2: One of the fuel injectors recorded a resistance value that isn't within the specification. This tells you that the fuel injector is bad. Replace the fuel injector.

How To Find The Bad Or Clogged Fuel Injector

There's a specific set of tests you can do to diagnose a cylinder misfire caused by a bad or clogged fuel injector.

Each test verifies that the misfiring cylinder is getting spark, compression, and fuel.

After each test, you'll know if the part's bad and causing the cylinder misfire, or if it's good to go. If it's fine, you move on to the next test. This testing strategy has saved me both time and money from swapping out parts that weren't causing the misfire issue.

These are the steps of my testing strategy:

- First, find the 'dead' cylinder.

- This is the most important first step. You can do this by connecting an automotive scan tool (or code reader) and reading the fault codes stored in your Neon's fuel injection computer's memory.

- After identifying the 'dead' cylinder, make sure it's receiving spark.

- It's important to check for spark using a spark tester.

- You can find this test explained step-by-step here: How To Test The DIS Ignition Coil (Chrysler 2.0L, 2.4L) (at easyautodiagnostics.com).

- Make sure that the dead cylinder's spark plug boot and the spark plug are NOT soaked (or swimming) in engine oil.

- You should also remove the spark plugs and check for cracks or carbon tracks (this is VERY important).

- Here's a real-life case study on carbon tracks and how they can cause cylinder misfire: Carbon Tracks Are A Common Cause Of Ignition Misfires (at: easyautodiagnostics.com).

- It's important to check for spark using a spark tester.

- If the 'dead' cylinder is getting spark, the next step is to make sure it has good compression.

- After ensuring the 'dead' cylinder's spark plug wire is delivering spark, you need to check for a low compression issue.

- This is one of the most overlooked tests when diagnosing a cylinder misfire or rough idle. You can find the test here:

- If the 'dead' cylinder has spark and good compression, the next step is to test the fuel injector's activation signal with a Noid light.

- If every test gives you the correct and expected result, the next step is to make sure the fuel injector is receiving its activation signal.

- The following tutorial on how to use a Noid light explains how to check for the fuel injector activation signal: (I know this isn't the most detailed article on the topic, but it should give you an idea of what's involved).

- How To Use A Noid Light And Where To Buy It (at: easyautodiagnostics.com)

- If the 'dead' cylinder has spark, good compression, and the fuel injector is being activated; the next step is to swap the fuel injector.

- If I find that I have a specific 'dead' cylinder and:

- The ignition system isn't behind the issue.

- The compression value of that cylinder is fine (compared to the rest of the cylinders).

- The fuel injector's resistance is fine and it's being activated by the fuel injection computer...

- I think the fuel injector is clogged, I then swap that fuel injector with an adjacent one.

- If I find that I have a specific 'dead' cylinder and:

The list of tests might look long and intimidating, but it's actually simple and doable. You can do them all with simple and affordable tools.

The key takeaway of this testing strategy is that it's a step-by-step elimination process. You check one component, and if it's good, you move on to the next. It's the exact approach a tech at the shop takes, and now you can do it yourself.

If this info saved the day, buy me a beer!