The 24X crankshaft position (CKP) sensor, located behind the crankshaft pulley, can easily be tested with a multimeter in Volts DC mode. In this tutorial I'm gonna' show you how to do this in 3 simple tests.

Although a scan tool is a must-have tool to diagnose any modern fuel-injected vehicle, you don't need one to test the 24X crankshaft position sensor.

NOTE: The 24X CKP sensor is also known as the high resolution CKP sensor.

Contents of this tutorial:

- Symptoms Of A Bad 24X Crankshaft Position (CKP) Sensor.

- Circuit Descriptions Of The Crankshaft Position Sensor.

- Where To Buy The 24X Crankshaft Position Sensor.

- TEST 1: Testing The 24X Crankshaft Position Signal.

- TEST 2: Making Sure The 24X CKP Sensor Has Power.

- TEST 3: Making Sure The 24X CKP Sensor Has Ground.

APPLIES TO: This tutorial applies to the following vehicles since they use the exact same 24X crankshaft position (CKP) sensor:

- 3.1L V6 Oldsmobile Cutlass Supreme: 1995, 1996, 1997.

RELATED TUTORIALS: The following tutorial will help you test the ignition coil packs and the ignition control module:

- How To Test The Ignition Coil Packs (GM 3.1L, 3.4L) (at: easyautodiagnostics.com).

- Testing The Ignition Module and Crank Sensor (GM 3.1L, 3.4L) (at: easyautodiagnostics.com).

WIRING DIAGRAMS: You can find the ignition system wiring diagrams here:

- Ignition System Wiring Diagram (1995 3.1L V6 Oldsmobile Cutlass Supreme).

- Ignition System Wiring Diagram (1996 3.1L V6 Oldsmobile Cutlass Supreme).

- Ignition System Wiring Diagram (1997 3.1L V6 Oldsmobile Cutlass Supreme).

Symptoms Of A Bad 24X Crankshaft Position (CKP) Sensor

The 24X CKP sensor allows the fuel injection computer to determine a more precise crankshaft position at lower RPM (under 2000 RPM).

As such, the 24X crankshaft position sensor only plays a role in the engine management system after the engine has started.

When it fails, you'll see one or more of the following trouble codes lighting up the check engine light:

- Code 36: Ignition Control 24X Signal Circuit Error (1995 OBD I system).

- P0336: 24X Reference Signal Circuit (1996+ OBD II system).

You may also see one of the following symptoms:

- Rough idle.

- Engine may start and stall.

If your 3.1L Oldsmobile Cutlass Supreme is cranking but not starting, more than likely be 24X CKP sensor is not at fault. Still, it's a good idea to test it since its testing procedure is not difficult.

Circuit Descriptions Of The Crankshaft Position Sensor

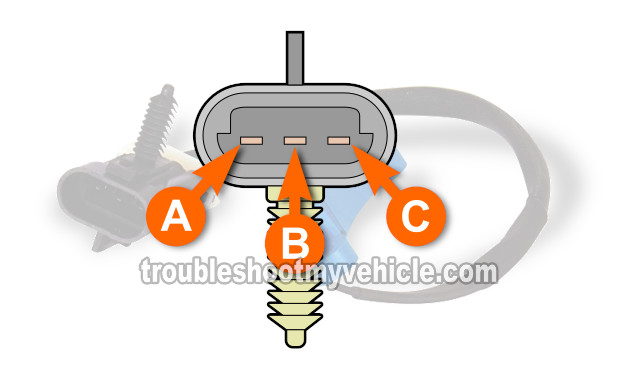

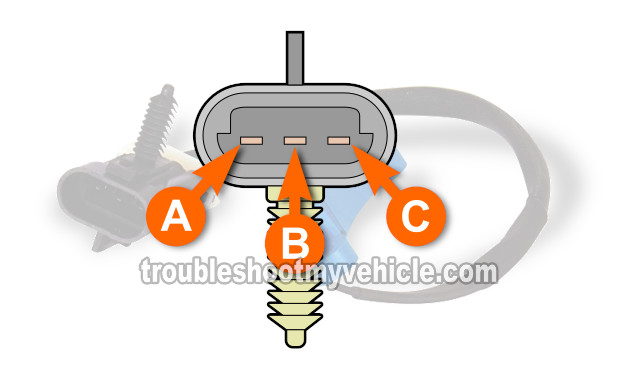

The 24X CKP sensor is a Hall Effect sensor with 3 wires coming out of its connector. This means that it needs 12 Volts and Ground to produce crankshaft position signal.

The 12 Volts the 24X CKP sensor needs to function are either provided by a fuse or the fuel injection computer (see tables below).

Ground is provided by the fuel injection computer.

The connector on the sensor itself has male spade terminals. The connector on the engine wiring harness has female terminals.

The following table has a brief job description of each of the 3 wires of the 24X CKP sensor.

| 1995 24X CKP Sensor Connector | ||

|---|---|---|

| Pin | Wire Color | Description |

| A | Pink (PNK) | 12 Volts (provided by F/INJ fuse) |

| B | Light blue with black stripe (LT BLU/BLK) | 24X CKP Signal |

| C | Pink with black stripe (PNK/BLK) | Ground (provided by PCM) |

| 1996-1997 24X CKP Sensor Connector | ||

|---|---|---|

| Pin | Wire Color | Description |

| A | Red with white stripe (RED/WHT) | 12 Volts (provided by PCM) |

| B | Light blue with black stripe (LT BLU/BLK) | 24X CKP Signal |

| C | Black (BLK) | Ground (provided by PCM) |

Where To Buy The 24X Crankshaft Position Sensor

Checkout the following links and comparison shop the 24X crankshaft position sensor for your 1995-1997 V6 Oldsmobile Cutlass Supreme of the 2 best known automotive parts manufacturers (Standard Motor Products and AC-Delco):

Important Safety Precautions And Tips

TIP 1: Place your vehicle on jack stands when raising it with a jack. Don't trust the jack to keep the vehicle raised!

TIP 2: Test the 24X CKP sensor with a cold engine. If the engine has been running for any length of time, let it cool down completely before starting any of the tests described in this tutorial.

Why? Because the 24X CKP sensor's pigtail connector is located under the exhaust manifold (radiator side). The exhaust manifold can get very hot and cause severe burns!

TIP 3: The 24X CKP sensor described in this tutorial is an on-car test. You should not remove it to test it.

TIP 4: To test for the 24X CKP sensor signal, it's important to turn the engine by hand. Specifically, you should turn the engine with a 1/2 inch ratchet and the appropriate socket on the crankshaft pulley bolt.

Do not use the starter motor to crank the engine during TEST 1.

TEST 1: Testing The 24X Crankshaft Position Signal

For our very first test, we're gonna' make sure that the 24X crankshaft position sensor is producing an ON/OFF voltage signal.

To be a bit more specific:

- ON is when the 24X CKP signal is at 10-12 Volts DC.

- OFF is when the 24X CKP signal is at 0 Volts.

To be able to see this ON/OFF voltage signal, it's important turn the engine manually. Using the starter motor to turn the engine will not give you the expected that result.

If the 24X crankshaft position sensor is bad, then it's going to stay stuck producing a single voltage value as the engine is manually turned.

In other words, the crankshaft position sensor is not going to produce the ON/OFF voltage signal as you manually turn the engine.

LOCATION OF THE 24X CKP SENSOR: The 24X CKP sensor is located behind the crankshaft pulley balancer.

IMPORTANT: The 24X sensor must be connected to its engine harness connector for this test to work. You'll need to connect your multimeter test lead to a back probe or a wire piercing probe to read the crank signal. You can see an example of a wire piercing probe and where to buy it here: Wire Piercing Probe.

NOTE: Don't have a multimeter or need to upgrade yours? Check out my recommendation: Buying A Digital Multimeter For Automotive Diagnostic Testing (at: easyautodiagnostics.com).

These are the test steps:

- 1

Raise the front passenger side of the vehicle and place it on a jack-stand.

- 2

Remove the water splash shield to access the crankshaft pulley bolt.

This is the plastic splash shield that protects the crankshaft pulley and drive belt from water splash. - 3

Place your multimeter in Volts DC mode.

- 4

Connect the black multimeter test lead to the battery negative (-) terminal.

- 5

Connect the red multimeter test lead to the LT BLU/BLK wire wire of the 24X CKP sensor connector.

The LT BLU/BLK wire is on the engine wiring harness side of the connector.

NOTE: The 24X CKP sensor must remain connected to its engine wiring harness connector to be able to read its signal. - 6

Turn the ignition key to the ON position but don't crank or start the engine.

- 7

Slowly turn the engine by hand using a 1/2" ratchet wrench and appropriate socket on the crankshaft pulley bolt. For the accuracy of the test, do not use the starter motor.

- 8

Your multimeter should read an ON/OFF voltage of 5 Volts and 0 Volts as you turn the engine.

ON is when the multimeter reads 4-5 Volts DC and OFF is when it reads 0 Volts DC.

Let's examine your CKP signal test result:

CASE 1: The 24X CKP sensor is producing the indicated ON/OFF DC voltage. This is the correct and expected test result and tells you that the 24X crankshaft position sensor is functioning correctly.

CASE 2: The 24X CKP sensor IS NOT producing the indicated ON/OFF DC voltage. This test result usually indicates the 24X CKP sensor is bad.

To be sure, the next step is to make sure that it's receiving 12 Volts. For this test go to: TEST 2: Making Sure The 24X CKP Sensor Has Power.