TEST 2: Making Sure The TPS Is Getting 5 Volts And Ground

Although it's rare for the throttle position sensor to be missing 5 Volts or Ground, it still a good idea to check for them if the TPS did not pass test one.

Why? Because if the TPS is missing 5 Volts or Ground, it's not going to produce a throttle plate angle voltage signal.

To test for these 5 Volts and Ground, we are going to do a simple multimeter voltage test.

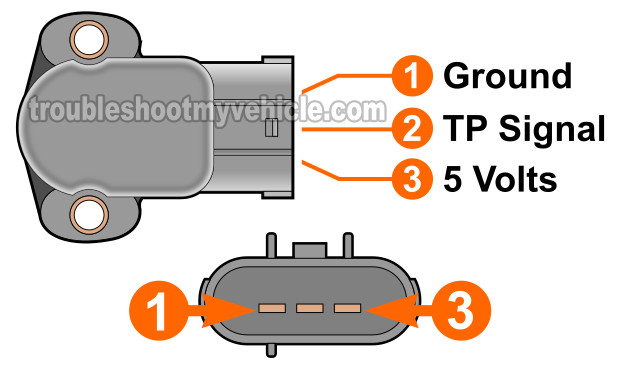

The wire that feeds 5 Volts to the TPS is the brown with white stripe (BRN/WHT) wire. This BRN/WHT wire connects to the TPS terminal labeled with the number 3 in the illustration above.

The wire they feeds Ground to the TPS is the grey with red stripe (GRY/RED) wire. This GRY/RED wire connect to the TPS terminal labeled with the number 1 in the illustration above.

NOTE: Be careful not to short-circuit the Ground wire to 12 Volts or you will fry your Ford Windstar fuel injection computer (since it's the computer that feeds the TPS with Ground). The multimeter voltage test indicated in the test steps below is a safe way of testing the Ground wire.

These are the test steps:

- 1

Check the BRN/WHT wire for power with the Key On Engine Off (KOEO). The BRN/WHT wire is the one that connects to terminal number 3

Connect the red multimeter test lead to the BRN/WHT wire and connect the black lead to the battery negative (-) post.

The multimeter should register 4.5 to 5 Volts DC. - 2

Check the GRY/RED wire for Ground with the Key On Engine Off (KOEO) (see illustration above). The GRY/RED wire is the one that connects to terminal number 1

Connect the black multimeter test lead to the GRY/RED wire and connect the red lead to the battery positive (+) post.

The multimeter should register battery voltage (12+ Volts).

Let's interpret your test results:

CASE 1: The TPS is getting 5 Volts and Ground. This is the correct test result.

Taking into account that you've reached this point because the TPS did not pass the test in TEST 1 and that it is getting 5 Volts and Ground, you can now correctly conclude that the TPS is defective. Your next step is to replace the throttle position sensor on your 1996-1999 3.8L Ford Windstar.

CASE 2: The TPS is not getting 5 Volts or Ground. Without 5 Volts or Ground the throttle position sensor will not work.

The next step is to find out why power or Ground is missing and resolve the issue. I can tell you from personal experience that usually what causes this to happen is an open circuit in the wires between the fuel injection computer and the TPS connector.

TPS Trouble Code Won't Go Away

I've diagnosed cases where the fuel injection computer was accusing the TPS as defective yet the center was not.

What I found out, in these cases, was that there was some other mechanical or electrical issue fooling the computer into thinking the TPS was defective.

If this is happening in your case, the following suggestions may help you save some time and money:

- Check to see if the TP sensor's wiring harness connector is broken.

- Specifically, check the connector's locking tab. It's a very common problem for the locking tab to break and cause a false contact condition.

- Check that the throttle plate idle stop screw isn't misadjusted.

- What I've seen quite a bit, is that the idle stop screw has been adjusted to increase the engine's idle RPM to mask a rough idle condition. But doing this usually causes the computer to set a TPS trouble code.

- Check the continuity of the wires between the fuel injection and the throttle position sensor.

- The idea behind this test is to make sure that there isn't an open circuit in the wiring between the TPS and the fuel injection computer.

- Check that the computer isn't defective. This can seem like quite a challenge but it's possible. This is how you can conclude that you have a defective fuel injection computer on your hands:

- Eliminate the throttle position sensor as defective first.

- Make sure that the wiring between the TPS and the computer has continuity. In other words there aren't any short circuits or open circuits in the wiring between these two.

- Confirm that the fuel injection computer's Ground wires are actually feeding it Ground. The best way to do this is to do a voltage drop test on each fuel injection computer's Ground wires.

- Confirm that the fuel injection computer has power in each of its power wires.

- After eliminating the TPS itself, after verifying the continuity of the TP sensors 3 wires (between its connector and the fuel injection computer), after verifying that the fuel injection has good Ground and power; then and only then can you conclude that there might be a problem with the computer internally.