In this tutorial, I'll walk you through the compression test and how to interpret its results step-by-step on the 3.8L V6 Ford Windstar.

Whether your Windstar is suffering a misfire condition or an engine no-start, your compression test results will let you know if a compression issue is behind the problem.

NOTE: You can find the 3.0L and 3.8L Ford Taurus (Mercury Sable) and 3.0L V6 Ford Ranger compression tests here:

- How To Do And Interpret An Engine Compression Test (1990-2007 3.0L V6 Ford Taurus, Mercury Sable).

- How To Test The Engine Compression (1991-1995 3.8L V6 Ford Taurus, Mercury Sable).

- How To Test The Engine Compression (1991-2008 3.0L V6 Ford Ranger) (at: easyautodiagnostics.com).

Contents of this tutorial:

ES ![]() You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (Ford 3.0L, 3.8L) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (Ford 3.0L, 3.8L) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 3.8L V6 Ford Windstar: 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002, 2003.

Symptoms Of Low Or No Engine Compression

In the majority of cases, engine compression problems will cause one of two problems:

- The engine does not start.

- The engine starts and runs, but runs with a misfire (rough idle).

On OBD II equipped vehicles, low compression problems will usually set a misfire trouble code:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

You're also gonna' see one or more of the following:

- Bad gas mileage.

- Engine burns oil when accelerating the vehicle on the road.

- Rough idle (or misfire) that goes away once the engine is accelerated.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make three recommendations to you:

Disclosure: As an Amazon Associate, I earn from qualifying purchases. If my tutorials help you, using these links is an easy way to support the site at no extra cost to you. Thank you!

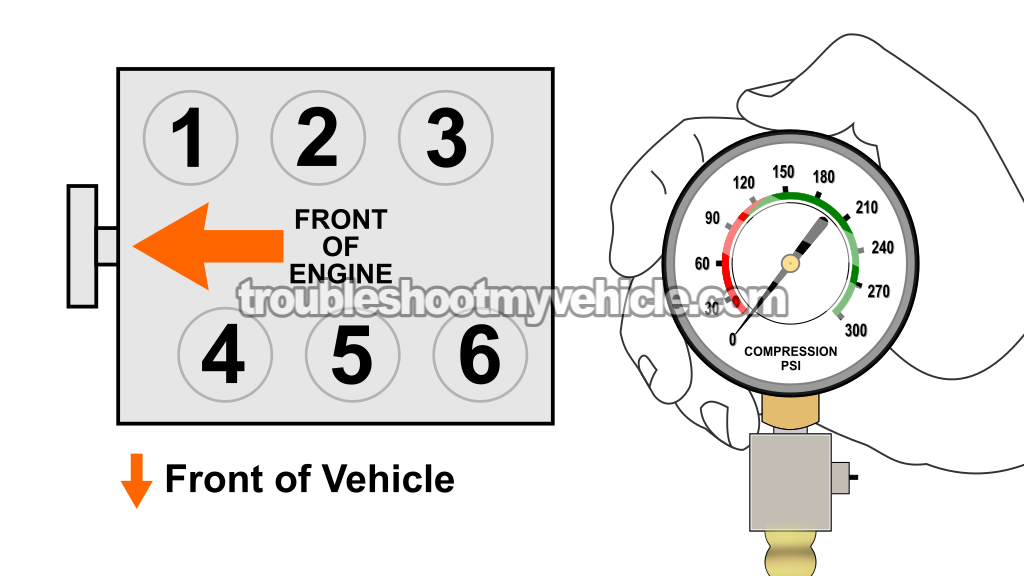

TEST 1: Engine Compression Test

The one thing that makes checking compression on the Ford Windstar's 3.8L engine a bit of a challenge is the fact that the spark plugs for cylinders 1, 2, and 3 —the ones facing the engine compartment firewall —aren't very easy to remove.

To get access to them, you'll need to remove the windshield wiper plastic cowling that covers the rear of the engine (see photo 2 of 2 in the image above —the arrow points to the plastic cowling). The following YouTube video explains the process: Ford Windstar Spark Plug Replacement!! (at: youtube.com).

Once you have the plastic wiper cowling removed, you'll have plenty of room to remove and install the spark plugs.

IMPORTANT: The one thing —the very important thing— you need to keep in mind is that you must remove the spark plugs with a completely cold engine. If the engine has been running for any length of time, let it cool down completely first. Otherwise, you could strip the spark plug hole threads in the aluminum cylinder heads. And let me tell you, that's a nightmare you definitely want to avoid.

OK, let's get testing:

- 1

Remove the plastic wiper cowling to access the rear bank spark plugs.

NOTE: The arrow in photo 2 of 2 points to the plastic wiper cowling. - 2

Disable the fuel system. You can do this by removing the fuel pump relay.

The reason you need to disable the fuel system is to keep the PCM from injecting fuel into the engine cylinders as you perform the compression test. - 3

Disable the ignition system. This can be done by simply disconnecting the ignition coil pack from its electrical connector.

NOTE: It's important to disable the ignition system so that you won't have spark firing off at the spark plug wires (while you do the compression test). - 4

Remove all of the spark plugs. As you're taking them out, be careful and don't drop any of them on the floor, or you could cause the spark plug's ceramic insulator to break, and this will cause a misfire!

- 5

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 6

Ask your helper to crank the engine once the compression gauge is set up and hand tight in the spark plug hole.

- 7

Once the needle stops climbing on your compression gauge, have him or her stop cranking the engine.

- 8

Record on paper the value at which the needle stopped and the number of the engine cylinder on a piece of paper.

- 9

Repeat steps 5 thru' 8 on the remaining five cylinders.

OK, let's make sense of all of the numbers you recorded for each cylinder:

CASE 1: You got 0 PSI on all six cylinders. This is not good. The engine won't start if all six cylinders have 0 PSI compression.

0 PSI compression across all six cylinders is usually the result of one the following conditions:

- Broken timing chain.

- Blown head gasket.

- Blown engine.

CASE 2: One or more cylinders had low compression. Up to a certain point this is normal. But if the low compression value or values are lower than 15% of the highest, then those cylinders will misfire.

Thankfully, we can easily figure out if these cylinders (with the low compression values) are causing a problem by doing a little math. Go to: Interpreting The Results Of The Engine Compression Test.

Interpreting The Results Of The Engine Compression Test

The cylinders will eventually suffer wear and tear (as the engine accumulates miles) and produce lower compression values. This doesn't happen overnight, but it will happen.

Now, uneven compression across the cylinders will not cause engine performance problems if the variation (in the compression values) does not vary more than 15%.

If in TEST 1 some of the cylinders have a lower compression value than the rest, then this section will help you figure out if those compression values are lower than 15% of the highest value. Because if they are, they're causing a problem.

There are one of two ways to find out: You can calculate this 15% difference with pen and paper or you can use my low compression calculator. You can find the low compression calculator here: Online Low Engine Compression Calculator (at: easyautodiagnostics.com).

If you want to manually calculate the 15% difference, here's what you'll need to do:

- STEP 1: Multiply the highest compression value by 0.15 (this is the decimal value of 15%).

- STEP 2: Round the result to the nearest one (for example: 25.6 would become 26).

- STEP 3: Subtract the result (the number that was rounded) from the highest compression value.

- ANSWER: The result of this subtraction is the lowest possible compression value any cylinder can have.

Now, let me give you a more specific example: Let's say that my engine compression test produced the following compression readings:

| Cylinder | Pressure |

|---|---|

| #1 | 165 PSI |

| #2 | 95 PSI |

| #3 | 155 PSI |

| #4 | 175 PSI |

| #5 | 165 PSI |

| #6 | 175 PSI |

My next step is to do the following calculation:

- STEP 1: 175 x 0.15 = 26.25.

- STEP 2: 26.25 = 26 (rounded to nearest one).

- STEP 3: 175 - 26 = 149.

- ANSWER: 149 PSI. Any cylinder with this compression (or lower) value will misfire.

Since cylinder #2 is only producing 95 PSI, I can now conclude that it's 'dead' and causing a misfire.

To find out if the lowest compression value you got from your engine compression test is within a good range, you'll need to do the same calculation. Of course, you'll need to use the highest compression value you got and not the one in the example.

Once you've found the 'dead' cylinder, the next step is to find out what's causing the low compression value. For this step, go to: TEST 2: Wet Engine Compression Test.

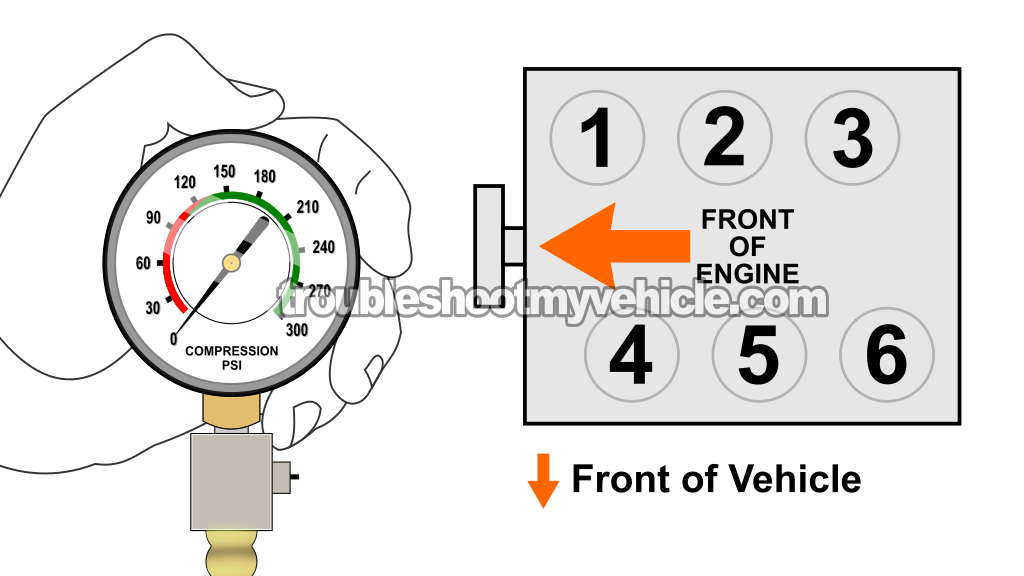

TEST 2: Wet Engine Compression Test

If you've identified one or more cylinders with zero or low compression, the next step is to find out what's causing that low reading in that specific cylinder.

To give you a little background, a low or zero compression value is usually caused by one of two things:

- Worn-out piston rings.

- Worn or damaged cylinder head valves.

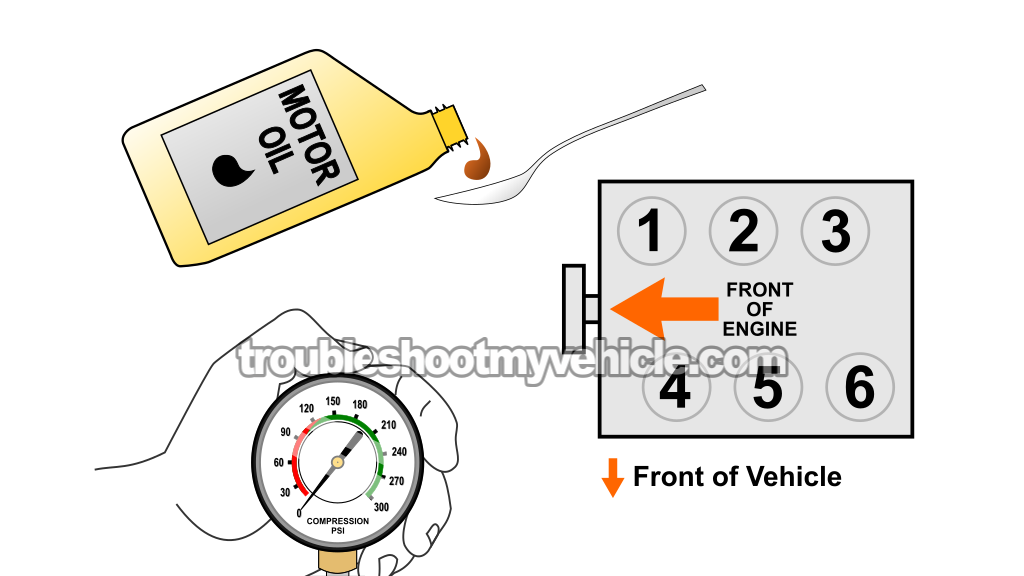

The cool thing is, we don't have to tear the engine apart to check these. We can perform a wet compression test, and the results will tell us exactly where the issue lies.

To be more specific, a wet compression test involves adding a small amount of engine oil to the cylinder (or cylinders) with low or zero PSI, and then checking compression again.

You're going to see one of two things happen:

- Compression shoots up —which tells us the problem is with the piston rings.

- Compression stays the same (just like in TEST 1) —which tells us the problem is with the cylinder head valves.

OK, this is what you need to do:

- 1

Add a small amount of engine oil to the cylinder that reported low compression or no compression in the 'dry' compression test.

The amount should be about 1 to 2 tablespoons of oil. - 2

Install the compression tester onto the cylinder. Do not use any type of tool to tightened the compression tester. Hand tight is fine.

- 3

When all is set up, have your helper crank the engine.

- 4

You'll get one of two results:

1.) The compression value will go up (from the one you recorded before).

2.) The compression value will stay the same.

Let's take a look at your test results:

CASE 1: The compression value shot up. This tells you that the piston compression rings are worn out and thus the problem is in the bottom end (block) of the engine in your 3.0L/3.8L Ford vehicle.

CASE 2: The compression value stayed the same. This test result tells you that the low compression in this specific cylinder is due to bad cylinder head valves.

More 3.8L V6 Ford Windstar Diagnostic Tutorials

I've written quite a few diagnostic tutorials for the 3.8-liter V6 Ford Windstar, and you can find them all in this index.

Here's a sample of the tutorials you'll find in the Windstar tutorial index.

- How To Test The MAF Sensor (1995 3.8L V6 Ford Windstar).

- How To Test The TPS (1996-1999 3.8L V6 Ford Windstar).

- How To Test The Fuel Pump (1995-1998 3.8L V6 Ford Windstar).

- How To Test For A Blown Head Gasket (1995-2003 3.8L V6 Ford Windstar).

If this info saved the day, buy me a beer!