TEST 3: Cylinder Compression Test

One of the most overlooked tests, to see if the head gasket is bad or not, is an engine compression test. Why? Well because most folks will do the two previous tests (TEST 1 and TEST 2) and they will not see the engine oil mixing with the coolant nor see the combustion gases jumping out of the open radiator and conclude everything is OK. And whatever information they have available never mentions testing the engine compression.

Well, now you know that it is possible for the head gasket to burn and not cause the oil to mix with coolant nor cause the exhaust gases to escape thru' the cooling system. In this test step, you'll be doing a compression test and more importantly, you'll be able to easily interpret those results to further confirm or exonerate a blown head gasket.

This test will see if the head gasket on your 5.2L, 5.9L Dodge Ram pickup has burned at a point between cylinders.

If this does happen, the compression/combustion of one cylinder to leak into the other and vice-versa and the compression readings will easily let us know this has happened.

NOTE: The engine compression test is explained in more detail here: How To Test Engine Compression (1989-2003 5.2L, 5.9L V8 Dodge Ram Pickup).

OK, here's what you need to do:

- 1

Disable the ignition system on your 5.2L, 5.9L Dodge Ram pickup. It's important that spark is not created and delivered to the spark plug wires.

You can easily accomplish this by disconnecting the ignition coil's electrical connector. - 2

Disconnect all spark plug wires (from their spark plugs).

IMPORTANT: Label the spark plug wires with the cylinder number they belong to, before you unplug them. This will help you reconnect them in the correct firing order when you're done with the test. - 3

Remove all 8 spark plugs.

- 4

Thread in the compression tester by hand, on the first spark plug hole you're gonna' start with.

NOTE: Do not use any tools to tighten the compression tester. Hand tightening the compression tester is more than enough to get the proper results. - 5

Have a helper crank the engine. Your job is to observe the compression tester.

- 6

Once the tester's needle stops climbing, have your assistant stop cranking the engine.

- 7

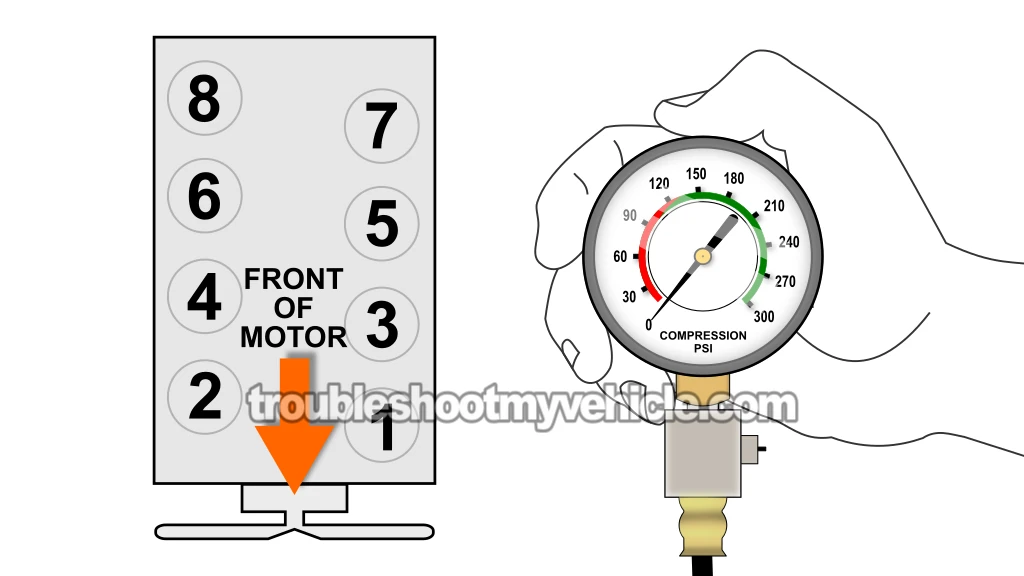

Write down the reading and what cylinder it belongs to (you can use the image in the image viewer to help you identify the cylinder) on a piece of paper.

- 8

Remove the compression tester and repeat the above steps in the remaining cylinders.

OK, before I jump into the above compression test result interpretations, let me give you some more detailed information as to what you're trying to accomplish with this test, if the head gasket is burned at a location between 2 cylinders, your compression test readings for bank 1 (or bank 2) will give you 2 good compression readings and 2 compression readings that will be 0 PSI. Let me give you a more specific example:

Let's say that I tested my 5.2L or 5.9L V8 Dodge Ram pickup and I got the following compression tester readings:

- Cylinder #1 = 165 PSI

- Cylinder #2 = 180 PSI

- Cylinder #3 = 0 PSI

- Cylinder #4 = 170 PSI

- Cylinder #5 = 0 PSI

- Cylinder #6 = 170 PSI

- Cylinder #7 = 175 PSI

- Cylinder #8 = 175 PSI

The compression readings for cylinders #3 and #5 would be a dead giveaway that the head gasket got fried between those two cylinders. Now in your 5.2L, 5.9L Dodge Ram pickup, you may not see those exact same cylinders with 0 PSI readings. It may be #1 and #3 or it may be #4 and #6. The key here, is that whatever cylinders are affected, two of them will have 0 PSI compression and they will be both be side by side and on the same bank.

OK, let's take a look at what your results mean:

CASE 1: All cylinder compression readings where normal. These compression gauge readings confirm that the head gasket is OK and not burned at a point between two cylinders.

OK, 3 out of 4 tests have confirmed that the head gasket on your 5.2L, 5.9L Dodge Ram pickup is not blown. But, but if you're not convinced, check out the last test: TEST 4: Using A Chemical Block Tester (Combustion Leak Tester).

CASE 2: Two side by side cylinders had 0 PSI compression. This engine compression reading confirms that the head gasket is burned thru' at the point between those two cylinders. You'll need to replace the head gasket.

TEST 4: Using A Chemical Block Tester (Combustion Leak Tester)

If your Ram pickup is still overheating, but the previous 3 tests don't confirm a blown head gasket and you have:

- Verified the engine coolant thermostat is good.

- The fan clutch is good.

- Water pump is good.

Then there's a good chance you've got a blown head gasket in its initial stages. The way to find out is by doing a block test.

A block test is another name for a combustion leak detector test. And let me tell you, that a block test is the best way to find out if the head gasket is blown or not in those cases that the previous 3 tests cannot confirm or disprove a blown head gasket.

This is how this test works:

- A blue liquid chemical, which is blue in color, is placed in the tester (see photo above).

- The tester assembly is then placed on the open radiator neck (you may have to drain some of the coolant in the radiator since this tool needs to ‘gulp’ some of the air inside the radiator).

- The engine is started.

- The rubber bellow is then squeezed to suck in the air up through the two fluid-filled chambers. As the air bubbles up through the fluid, it will cause a chemical reaction.

- If the blue chemical turns yellow (for gasoline engines), combustion gases are entering the radiator. This result confirms a head gasket failure, a cracked block, or a cracked cylinder head issue.

- If the blue chemical doesn't change color, you can conclude that you don't have a head gasket failure, a cracked block, or a cracked cylinder head issue.

You can shop for a block tester here:

Frequently Asked Questions

1.) How do I know if a cylinder head is cracked?

- The only reliable way to find out is to remove the cylinder head and inspect it closely. If the crack is large, you may be able to see it with the naked eye.

- But not all cracks are easy to spot. That's why it's super important to have a professional engine machine shop do a pressure test —this method can reveal hidden cracks that aren't visible during a basic inspection.

2.) Is it necessary to resurface the cylinder head?

- Yes, resurfacing is strongly recommended —especially if the engine overheated. Don't reinstall the cylinder heads without making sure they have been resurfaced by a professional machine shop.

- The only time you might skip resurfacing is if both you and the machine shop confirm the head is perfectly flat using a straight-edge and feeler gauge. If there's any warping at all, resurfacing is a must to ensure a proper seal.

3.) Should I remove both cylinder heads?

- Yes —especially if the engine overheated.

- Removing both heads allows you to inspect them thoroughly and, if needed, have a machine shop test each one for cracks and warpage. It's the best way to make sure the job doesn't comes back.

4.) Is it a good idea to use a "Head Gasket Repair In A Can" product?

- No! Don't do it. It's not a good long-term solution.

- While these sealers might offer a temporary fix, they don't actually repair the problem. Even if they seem to help at first, the head gaskets will still need replacing sooner or later.

- And they often cause more trouble than they solve:

- Radiator and heater core blockages due to sealant buildup.

- Restricted coolant flow caused by gunk collecting in the coolant passages —leading to higher temperatures and potential engine damage.

More 5.2L, 5.9L V8 Dodge Ram Pickup Tutorials

There are several more 5.2L, 5.9L V8 Dodge Ram Pickup specific 'how to' tutorials that I've written and you can find them here:

If this info saved the day, buy me a beer!