CRANK SENSOR TEST 2: Verifying The Crank Sensor Has Power

In this test step, you're going to verify that the crankshaft position sensor is getting power. As mentioned earlier, this power comes in the form of 5 or 8 Volts from the PCM. Don't worry about what specific voltage your specific vehicle should output since it will be either one or the other.

IMPORTANT: You got to be very careful not to short this wire to Ground since you run the risk of damaging the PCM. Also, do not use a test light to verify this voltage, use a multimeter.

- 1

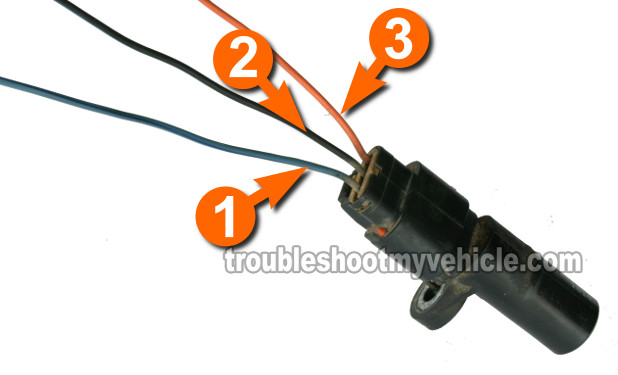

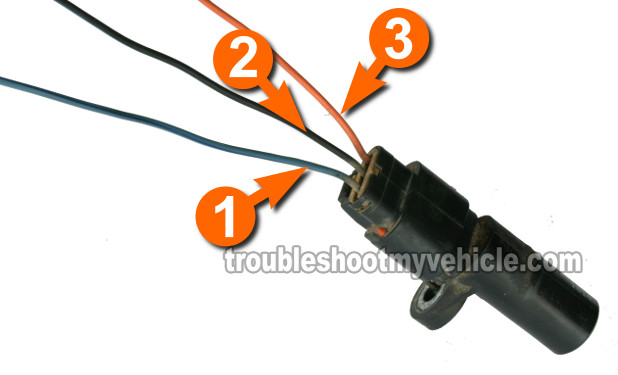

With your multimeter still in Volts DC mode, probe the wire identified with the number 3 in the image viewer, with red multimeter test lead. Do not probe the front of the crankshaft position sensor connector to verify this voltage. Pierce the wire with an appropriate tool.

- 2

Ground the black lead of the multimeter to a good Ground point on the engine.

- 3

When everything is set up, have your helper turn the key to the On position.

- 4

If all is good with this circuit, your multimeter should register 5 or 8 Volts.

OK, let's interpret the multimeter test results you just obtained. Choose from the CASES below that best match your specific results:

CASE 1: The multimeter registered 5 or 8 Volts DC when the key was turned On. This let's you know that the crankshaft position sensor is being fed with power (8 Volts) from the PCM. There is still one more test to do, before we can condemn the crankshaft position sensor as bad, and that is to test the Ground circuit. Go to: Crank TEST 3: Verifying The Crank Sensor's Ground.

CASE 2: The multimeter DID NOT register 5 or 8 Volts DC when the key was turned On. Recheck your connections and try the test again.

If the multimeter still does not register 8 Volts, then this result lets you know that the reason there was no ON/OFF 5 Volt signal, registered in TEST 1, is because the crankshaft position (CKP) sensor is not getting power. You have now eliminated the crankshaft position sensor as the cause of the no-start condition.

Solving the issue that is causing these missing 5 or 8 Volts will solve the no-start condition of your Chrysler 2.7L, 3.3L, or 3.8L equipped car.

CRANK SENSOR TEST 3: Verifying The Crank Sensor's Ground

In this test step, you're going to verify that the crankshaft position sensor is getting Ground. As mentioned earlier, the Ground path is completed inside the PCM.

IMPORTANT: You got to be very careful not to short this wire to power (battery voltage) since you run the risk of damaging the PCM. Also, do not use a test light to verify this voltage, use a multimeter.

OK, to get this kettle boiling, this is what you need to do:

- 1

With your multimeter still in Volts DC mode, probe the wire identified with the number 2 in the image viewer, with black multimeter test lead. Do not probe the front of the crankshaft position sensor connector to check this Ground. Pierce the wire with an appropriate tool.

- 2

Connect the red lead of your multimeter to the battery positive (+) terminal.

- 3

When everything is set up, have your helper turn the key to the On position.

- 4

If all is good with this circuit, your multimeter should register battery voltage (12+ Volts).

Choose from the CASES below that best match your specific results:

CASE 1: The multimeter registered 12 Volts DC when the key was turned On. Then the crankshaft position sensor is getting a good Ground. This results confirms that the crankshaft position (CKP) sensor is bad. Replace the crankshaft position sensor.

Here's why: A good working crankshaft position sensor, when it receives power and Ground and the engine is cranking, will generate an ON/OFF 5 Volt signal. Now, in your particular case, in TEST 1 you verified the crankshaft position sensor is not creating its ON/OFF 5 Volt signal. In TEST 2 you confirmed that it's being fed with power (5 or 8 Volts) and in this test step, you have verified that it's getting a good Ground. Therefore the crankshaft position sensor is bad. Replace the crankshaft position sensor.

CASE 2: The multimeter DID NOT register 12 Volts DC when the key was turned On. Recheck your connections and try the test again.

If the multimeter still does not register 12 Volts, then this result lets you know that the crank does not have a good sensor Ground. You have now eliminated the crankshaft position sensor as the cause of the no-start condition, since without this Ground, the crankshaft position sensor will not work.