An engine compression test is fast becoming a key test in diagnosing a hard to troubleshoot misfire condition.

In this tutorial, you'll learn how to do the engine compression test and, more importantly, how to interpret the results of the test on your Jeep 4.0L Wrangler, 4.0L Cherokee, or 4.0L Grand Cherokee.

Contents of this tutorial:

![]() You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (4.0L Jeep) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar La Compresión Del Motor (4.0L Jeep) (at: autotecnico-online.com).

Important Tips

To successfully accomplish the tests in this article, here are some important tips:

TIP 1: Be alert and take all necessary safety precautions, since you'll be working around a cranking engine.

TIP 2: If the engine has been running for any length of time, let it cool down completely before removing the spark plugs.

TIP 3: Once you install the compression tester, hand tighten it only. Do not use any type of tool to tighten it.

TIP 4: If you're trying to solve a misfire condition (codes: P0300, P0301, P0302, P0303, P0304, P0305, P0306) or a rough idle condition, I recommend that you test for spark first.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make two recommendations to you:

1) Which one to buy: The engine compression tester that I have always used is the Actron CP7827 Compression Tester Kit. My only complaint about this engine compression tester is that it does not come with a case to store it in.

2) Where to buy: You can buy an engine compression tester just about anywhere, but you'll end up paying more for it (especially at your local auto parts store). The above links will help you comparison shop. I think you'll agree it's the better way to save money on the compression tester!

TEST 1: Dry Engine Compression Test

As you may already know, each cylinder in the engine of your 4.0L Jeep Cherokee (or Grand Cherokee, Wrangler) needs spark, air, and fuel to run. If any one of these components of the combustion process are missing in any of the six engine cylinders, the engine is gonna' run rough or suffer a misfire condition.

But what often gets overlooked, is the mechanical condition of the cylinder, when diagnosing a rough idle, misfire condition. This is where the following engine compression test comes in handy.

These are the test steps:

- 1

Disable the fuel system by removing the ASD Relay or disconnecting all 6 fuel injectors from their electrical connector.

- 2

Disable the ignition system. It's important that the ignition system not create and deliver spark to the spark plug wires.

You can disable the ignition system by disconnecting the ignition coil (distributor type ignition system). - 3

Disconnect the spark plug wires from the spark plugs. Label them before unplugging them from the spark plugs.

NOTE: This step only applies to ignition distributor systems. - 4

Remove all 6 spark plugs.

Be careful and don't to drop any of them, since dropping them can brake the ceramic insulator and then you'll have a misfire on your hands. - 5

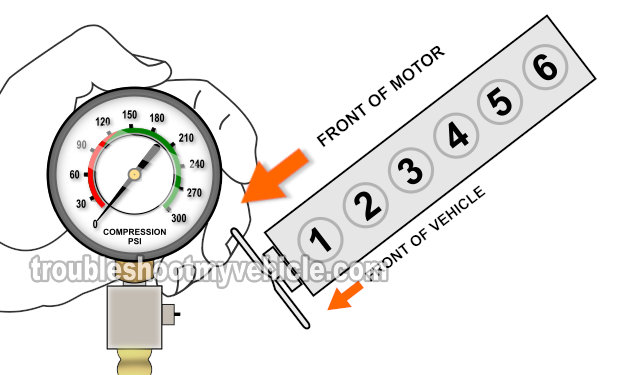

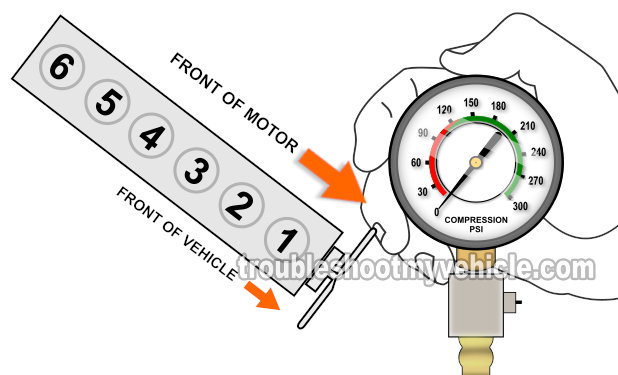

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder (this is the spark plug hole closest to the drive belt).

Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 6

When everything's in place, have someone crank the engine (or you can use a remote start switch) while you watch the needle on the compression tester.

- 7

When the needle stops climbing have your helper stop cranking the engine.

- 8

Write this engine compression value down, along with cylinder number.

- 9

Repeat this test on the remaining 5 cylinders.

Let's take a look at what your test results mean:

CASE 1: Low or no compression in 2 or all 6 cylinders. This test result indicates a serious internal problem.

The most common issues would be:

- Blown head gasket.

- Broken timing chain.

- Engine threw a rod.

CASE 2: Low compression in one or more cylinders. Up to a certain point this could be normal.

But if these values vary too much, then you're gonna' have a bonafide misfire on your hands.

The next step is to do some math to find out if this low compression value is within a normal parameter or not. Go to: Interpreting Your Compression Test Results.