Testing the compression of all 6 cylinders on the 3.0L equipped Chrysler, Dodge, or Plymouth cars/mini-vans is becoming a standard test when diagnosing a hard to find misfire (rough idle) or a no-start condition, especially if the vehicle has a lot of miles on it.

In this tutorial, I'll walk you through the entire process in a step-by-step fashion and help you interpret your compression test results to see if one or several cylinders have low (or no) compression.

Contents of this tutorial:

Tools You'll Need:

- Compression Gauge Tester.

- A Helper

- Pen and Paper

Symptoms Of Low Or No Engine Compression

Engine compression problems usually fall into two specific categories:

- One or more (but not all) cylinders have low or no compression.

- No compression in all 6 cylinders.

Here are some more specifics about the above two conditions.

One or more (but not all) cylinders have low or no compression: This is probably the most common problem affecting vehicles with a lot of miles or that have had a life of severe wear and tear and is usually due to worn cylinder head valves or worn piston rings.

The most obvious symptom of this type of problem is a rough idle that usually stops as you accelerate the engine.

Here are some more specific symptoms you'll see:

- Misfire codes (if the vehicle is OBD II equipped) lighting up the check engine light:

- P0300: Random Cylinder Misfire.

- P0301: Cylinder #1 Misfire.

- P0302: Cylinder #2 Misfire.

- P0303: Cylinder #3 Misfire.

- P0304: Cylinder #4 Misfire.

- P0305: Cylinder #5 Misfire.

- P0306: Cylinder #6 Misfire.

- Engine misses at idle.

- Lack of power.

- Blue smoke coming out of the tailpipe at idle and/or when accelerating (this is engine oil burning in the cylinders).

No compression in all 6 cylinders and your 3.0L equipped Chrysler car or mini-van won't start. It'll crank but not start. This usually indicates that your vehicle's timing belt is broken, or one or both of the head gaskets have failed, or that the engine is blown.

When you have a situation where you have no compression on ALL 6 cylinders, you'll see:

- The engine cranks very fast and this fast cranking speed is very noticeable.

- The ignition system is not creating spark (only occurs if timing belt is broken).

- Fuel pump is working and providing pressure.

Let's get testing to see what's happening to your 3.0L equipped Chrysler, Dodge, or Plymouth car/mini-van.

Which Compression Tester Should I Buy?

There are lot of engine compression testers to choose from and many places to buy them. I'm gonna' make two recommendations to you:

1) Which one to buy: The engine compression tester that I have always used is the Actron CP7827 Compression Tester Kit. My only complaint about this engine compression tester is that it does not come with a case to store it in.

2) Where to buy: You can buy an engine compression tester just about anywhere, but you'll end up paying more for it (especially at your local auto parts store). The above links will help you comparison shop. I think you'll agree it's the better way to save money on the compression tester!

TEST 1: The ‘Dry’ Engine Compression Test

To do an engine compression test, you'll need an engine compression tester.

You don't have to buy one since you can borrow one from your local auto parts store (like AutoZone or O'Reilly Auto Parts) for a cash deposit, which you'll get back once you return the tester.

If you need help deciding where to buy one or which one to buy, take a look at my recommendations: Which Compression Tester Should I Buy?

IMPORTANT: You'll be working around a cranking engine, so you have to be careful and stay alert at all times. Think safety all of the time!

This is what you'll need to do:

- 1

Disconnect the ASD relay. This will prevent fuel from being injected into the cylinders as you crank the engine.

- 2

Disconnect the ignition coil from its electrical connector. This is just to make sure that the ignition coil does not fire off spark during the compression testing of the cylinders.

- 3

Remove all 6 spark plugs. As your taking them out, be careful and don't drop any of them on the floor, or you could cause the spark plug's ceramic insulator to break, and this will cause a misfire!

IMPORTANT: You should label each spark plug wire with its location before you remove the spark plugs so that you can connect them (the spark plug wires) back to the correct spark plug once you're done with the compression test. - 4

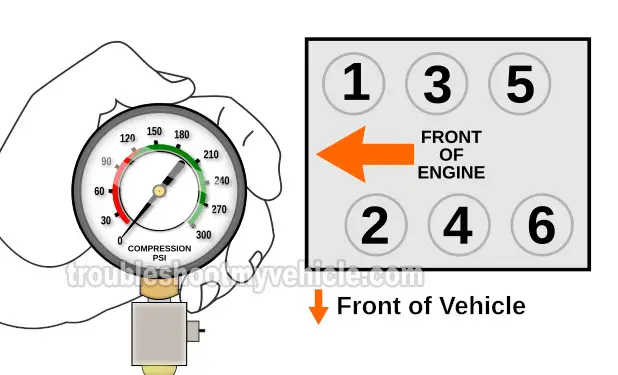

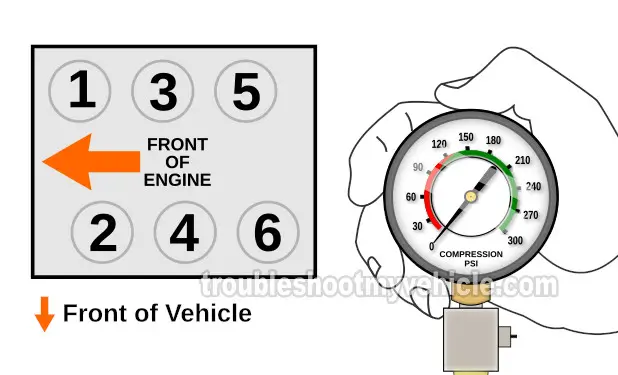

Thread the engine compression gauge into the spark plug hole for the number 1 engine cylinder.

Hand tighten the compression gauge only! Do not use any type of tool to get it tight. - 5

Have a helper crank the engine, when the test is set up, as you observe the needle on the compression tester's gauge.

- 6

Once the needle on the gauge stops climbing, have him or her stop cranking the engine.

- 7

Write down the compression test result and the cylinder the test result belongs to.

- 8

Repeat the test in the other 5 cylinders.

OK, let's interpret your compression test results.

CASE 1: Low or no compression in 2 side by side cylinders (of the same bank). This indicates a problem that's usually caused by:

- Blown head gasket.

CASE 2: No compression in ALL cylinders. This isn't good and indicates that your 3.0L equipped Chrysler car or mini-van has serious engine mechanical problems.

The most common issues would be:

- Broken timing belt. You can find the timing belt test here: How To Test For A Broken Timing Belt (1998-2000 3.0L SOHC Chrysler).

- Engine threw a rod.

CASE 3: Low or no compression in one or two cylinders (that are NOT side by side on the same bank). Up to a certain point, the low compression values could be normal.

To find out if they are normal or not, we now need to a simple math calculation to find out if this test result is within normal specs or not. Go to: TEST 2: ‘Wet’ Engine Compression Test