In this tutorial, I'll walk you through a super easy method to check the internal resistance of the fuel injectors on your 2.4L Caravan (Grand Caravan, Voyager, and Grand Voyager).

At first glance, you might think it's difficult to test them since they're located under the intake manifold plenum, but you'll be surprised at how simple the test actually is.

I'll help you figure out if they have a short-circuit or open-circuit issue. All of the test steps are explained in a step-by-step manner. I'm also including a testing strategy that'll help you find a clogged fuel injector.

Contents of this tutorial:

ES ![]() You can find this tutorial in Spanish here: Cómo Probar Los Inyectores (1996-1997 2.4L Caravan, Grand Caravan, Voyager, Grand Voyager) (at: autotecnico-online.com).

You can find this tutorial in Spanish here: Cómo Probar Los Inyectores (1996-1997 2.4L Caravan, Grand Caravan, Voyager, Grand Voyager) (at: autotecnico-online.com).

APPLIES TO: This tutorial applies to the following vehicles:

- 2.4L Dodge Caravan: 1996, 1997

- 2.4L Dodge Grand Caravan: 1996, 1997.

- 2.4L Plymouth Voyager: 1996, 1997.

- 2.4L Plymouth Grand Voyager: 1996, 1997.

You can find the fuel injector resistance test for the 1998-2000 2.4L Caravan and Voyager here:

CYLINDER MISFIRE DIAGNOSTICS:

- How To Troubleshoot A Cylinder Misfire (1996-2007 2.4L Chrysler, Dodge, And Plymouth Minivan).

- Common Causes Of Spark Plug Failure (1996-2007 2.4L Chrysler, Dodge, And Plymouth Minivan).

Symptoms Of A Bad Fuel Injector

It's been my experience over the years of diagnosing fuel injectors, that you'll usually see similar symptoms when they fail, whether they're clogged or experiencing an electrical issue with their internal winding.

The most common symptoms you'll encounter are:

- Rough idle: When you come to a stop, the engine idles rough (shakes) due to one or more injectors not spraying fuel evenly.

- Lack of power: A faulty fuel injector will cause changes to the air/fuel mixture and it'll feel like you're not getting the power you should when you step on the gas pedal.

- Engine hesitation under load: The engine struggles or hesitates when stepping on the gas pedal when one or more fuel injectors don't supply enough fuel.

- Cylinder misfire trouble codes: One or more of the following trouble codes will be stored in the fuel injection computer's memory:

- P0300: Random Cylinder Misfire.

- P0301: Misfire In Cylinder #1.

- P0302: Misfire In Cylinder #2.

- P0303: Misfire In Cylinder #3.

- P0304: Misfire In Cylinder #4.

- Poor Fuel Economy: Even just one faulty fuel injector means the engine has to work harder, using more fuel.

While this tutorial mainly focuses on checking the internal winding of the fuel injectors (for a short-circuit or open-circuit problem), I've also included a testing strategy that'll help you identify any clogged fuel injectors -or- the root cause of the cylinder misfire causing your engine to run rough in idle RPM. You can find it here: How To Find The Bad Or Clogged Fuel Injector.

Checking The Resistance Of The Fuel Injectors

To see if any of your fuel injectors have an internal electrical problem, we'll measure their resistance using a multimeter.

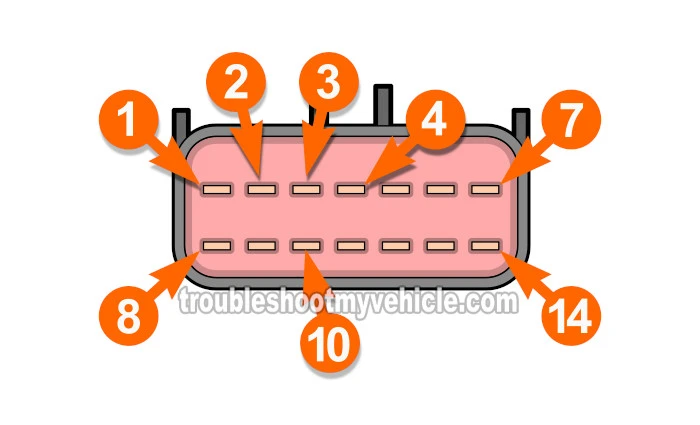

The really cool thing is that you won't need to remove the intake manifold plenum to test them. Why? Because you'll be testing them from the fuel injector harness connector, as shown in photos 1, 2, and 3 above.

Don't worry, testing the fuel injectors, to see if they're fried internally or not, is a very easy thing to do on your minivan equipped with the 2.4L engine.

NOTE: All of the resistance tests are done on the fuel injector harness connector with male spade terminals.

NOTE: The fuel injector resistance specification is 12 Ohms when the engine is at 68°F. This basically means the engine should be cold, or in other words, not recently run. If it has, let it cool down all the way before checking the fuel injectors.

Here are the test steps:

- 1

Place your multimeter in Ohms mode.

- 2

Disconnect the fuel injector harness from the engine wiring harness connector.

NOTE: All tests are done on the fuel injector harness connector which has male spade terminals. - 3

Probe terminals 1 and 10 with the multimeter test leads to test injector #1.

Your multimeter should register approximately 12 Ohms. - 4

Probe terminals 2 and 10 with the multimeter test leads to test injector #2.

Your multimeter should register approximately 12 Ohms. - 5

Probe terminals 3 and 10 with the multimeter test leads to test injector #3.

Your multimeter should register approximately 12 Ohms. - 6

Probe terminals 4 and 10 with the multimeter test leads to test injector #4.

Your multimeter should register approximately 12 Ohms.

Let's examine your test results:

CASE 1: All fuel injector resistances are within the specified value. This is the correct test result, and it confirms that none of the fuel injectors have an internal short-circuit or open-circuit problem.

If you suspect a clogged fuel injector (that the resistance test can't detect), proceed to the next section: How To Find The Faulty Or Clogged Fuel Injector.

CASE 2: One of the fuel injectors recorded a resistance value that's not within specification. This indicates that the fuel injector is faulty. Replace the fuel injector.

How To Find The Bad Or Clogged Fuel Injector

As I mentioned earlier, fuel injectors can fail in two main ways. Checking for internal electrical issues is pretty straightforward, as you've seen in the test steps above.

Where it gets challenging is diagnosing a clogged injector. In this section, I'll share the testing strategy I always use to identify a clogged injector.

Also, if you're stumped on where to begin diagnosing a cylinder misfire problem, this section will help you get started and find out its root cause.

- First, find the 'dead' cylinder.

- This is the most important first step. You can do this by connecting an automotive scan tool (or code reader) and reading the fault codes stored in your minivan's fuel injection computer's memory.

- After identifying the 'dead' cylinder, make sure it's receiving spark.

- It's important to check for spark using a spark tester.

- You can find this test explained step-by-step here: How To Test The Ignition Coil (2.4L Caravan, Grand Caravan, Voyager, Grand Voyager) (at easyautodiagnostics.com).

- Make sure that the dead cylinder's spark plug boot and the spark plug are NOT soaked (or swimming) in engine oil.

- You should also remove the spark plugs and check for cracks or carbon tracks (this is VERY important).

- Here's a real-life case study on carbon tracks and how they can cause cylinder misfire: Carbon Tracks Are A Common Cause Of Ignition Misfires (at: easyautodiagnostics.com).

- It's important to check for spark using a spark tester.

- If the 'dead' cylinder is getting spark, the next step is to make sure it has good compression.

- After ensuring the 'dead' cylinder's spark plug wire is delivering spark, you need to check for a low compression issue.

- This is one of the most overlooked tests when diagnosing a cylinder misfire or rough idle. You can find the test here:

- If the 'dead' cylinder has spark and good compression, the next step is to test the fuel injector's activation signal with a Noid light.

- If every test gives you the correct and expected result, the next step is to make sure the fuel injector is receiving its activation signal.

- The following tutorial on how to use a Noid light explains how to check for the fuel injector activation signal: (I know this isn't the most detailed article on the topic, but it should give you an idea of what's involved).

- How To Use A Noid Light And Where To Buy It (at: easyautodiagnostics.com)

- If the 'dead' cylinder has spark, good compression, and the fuel injector is being activated; the next step is to swap the fuel injector.

- If I find that I have a specific 'dead' cylinder and:

- The ignition system isn't behind the issue.

- The compression value of that cylinder is fine (compared to the rest of the cylinders).

- The fuel injector's resistance is fine and it's being activated by the fuel injection computer...

- I think the fuel injector is clogged, I then swap that fuel injector with an adjacent one.

- If I find that I have a specific 'dead' cylinder and:

Don't let the list of tests intimidate you. They're all very doable and don't require expensive diagnostic tools. The tests listed above are all about a process of elimination. You test one component, and if it's good, you move on to the next. Keep going until you find the one that tests bad —that's the component you'll need to replace to solve the problem. It's the same approach the technician at the shop would take, and now you can do it yourself.

If this info saved the day, buy me a beer!